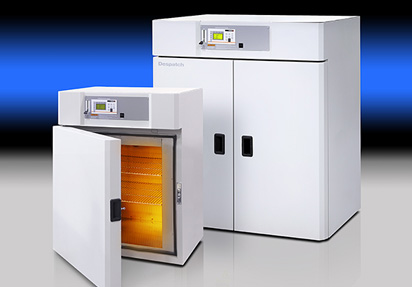

LAC High Performance Benchtop Oven

The horizontal recirculating airflow and

exceptional temperature uniformity of the LAC benchtop oven make it a good

fit for a variety of applications in the healthcare market. The LAC is

commonly used for curing plastic and non-volatile composite coatings and

polymers on medical devices, warming materials to soften and fit to a

prosthetic mold, sterilizing glassware and basic drying.

LEARN MORE REQUEST A QUOTE

ONLINE

STORE