Industrial ovens are products meant to last, even though their operational temperatures are quite high. They can, eventually, stop working for a variety of reasons and cause a costly repair. A good idea is to read the manual to know how the care and maintenance of industrial ovens looks like. However, if you’re not an expert, one way to avoid unwanted malfunctions is to have licensed maintenance regularly. It will help you maximize the oven’s lifespan, as well as upkeep the quality of the components.

Although the maintenance routine depends on the manufacturer and the model of the oven, you will get the schedule along with the product when you buy it. Let’s see what is included in troubleshooting of gas fired ovens.

1. Checking the Airflow

Restricted airflow can cause a change in the temperature profile and reduce the oven’s performance. It can also lead to the breakdown of certain components.

To prevent the damage, you should make sure that all fans are working properly and that the key parts of industrial ovens are devoid of any dirt. Moreover, the oven chamber, ventilation and ductwork should be in top condition to avoid premature component deterioration.

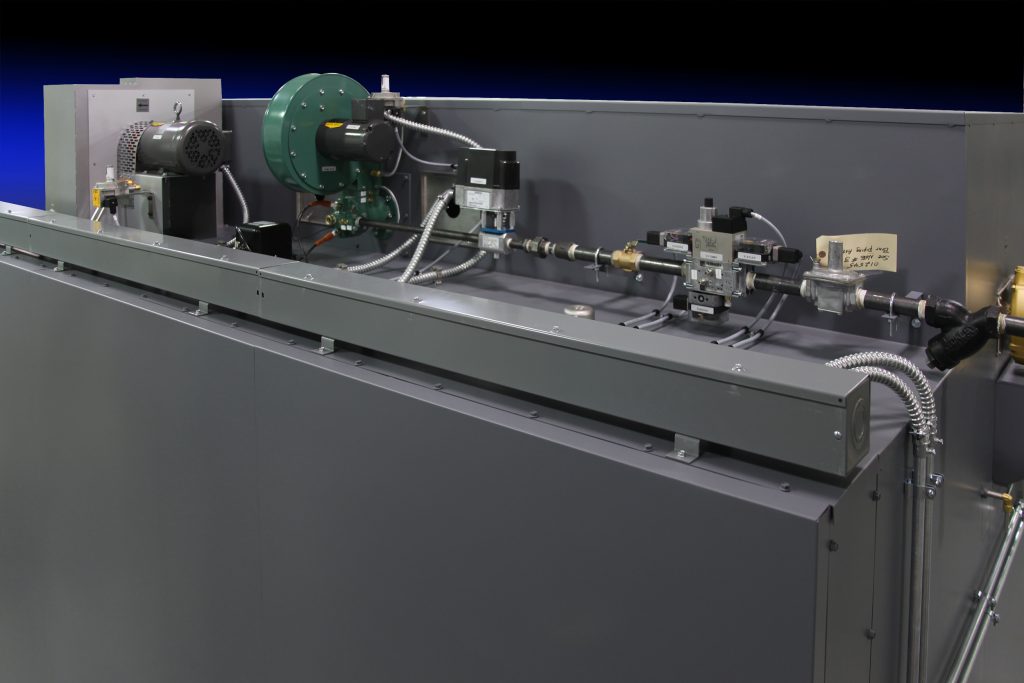

2. Air Pressure Switches on Industrial Ovens

The damage on air pressure switches is the most common cause of an industrial oven failure. Those elements actuate the electronic switch and they need to be checked often and replaced when the manufacturer advises so.

3. Examining the Sensors and Connectors’ Health

The material being processed in the oven could easily end up damaged if one sensor doesn’t respond. Even worse, the oven could completely shut down.

Two main issues could be causing the problem. You might have a broken extension lead or a broken thermocouple in the oven. You should remove the thermocouple from the oven to check if there are cracks or damage. A routine replacement and inspection should prevent the problem.

4. Using the Correct Power Supply

Although it sounds silly, the correct power supply can make or break the overall performance of a lab oven. The oven will have a poorer performance if operating on power reduction. Under voltage current can cause a component failure as well. So, ensure the oven works at reasonable voltage supply.

5. Inspecting the Heating Elements

The heating elements could easily damage if they are of bad quality. You should check the tubular elements and see if there are any contaminants and if any terminals are tight. Loose connections between them will eventually cause the components to burn out.

In case you inspected every part, make sure no element has become distorted. If it has, consider replacing the heating element or consult an expert on industrial ovens.

6. Checking for Heat Loss

Regularly checking heat seals and doors will tell you if there’s unnecessary heat loss in the oven. Also, if there’s light in the oven, make sure to always use a port plug. It will reduce heat loss.

7. Maintaining Industrial Oven’s Cleanliness

A gas-fired oven’s powder coating systems get covered in dust particles due to the heating procedure. The particles can badly affect the oven’s performance and it is best to conduct a monthly cleaning. As for the surface of the oven, you can use cleaning agents recommended by the manufacturer.

Certain steps in care and maintenance of industrial ovens can be done in minutes. Despatch offers training courses and high value subscription programs to assist you. If you’re not an expert, however, leave the job to licensed professionals who will troubleshoot your gas fired oven.