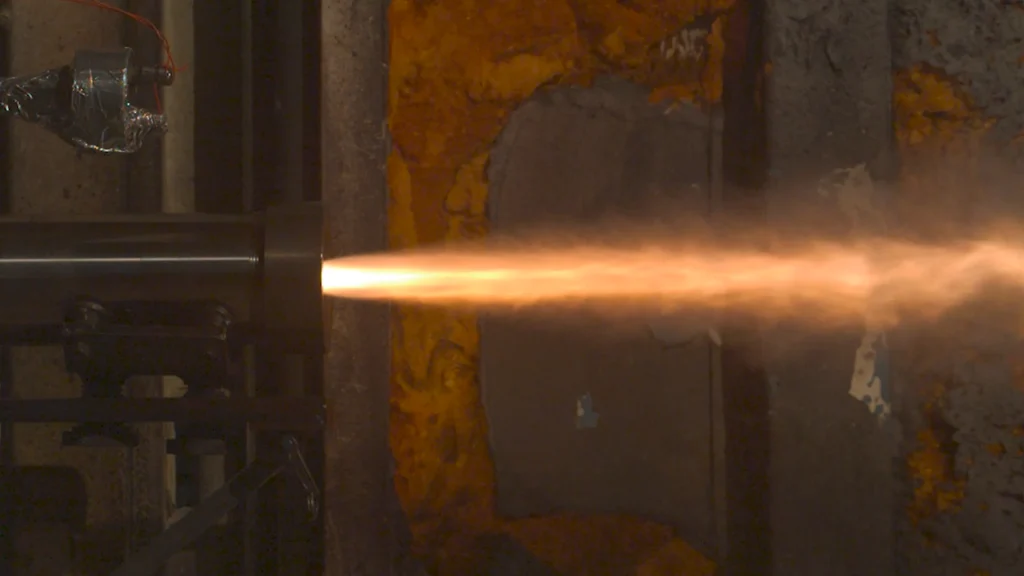

Titomic has achieved a significant validation milestone for its cold-spray additive manufacturing platform, announcing that a thrust chamber produced using Titomic Kinetic Fusion™ successfully completed a hot-fire test for a major U.S. aerospace and defense prime contractor. The test subjected the component to extreme thermal and mechanical loads—conditions that typically expose micro-defects or structural weaknesses in additively manufactured propulsion hardware.

The thrust chamber demonstrated strong structural integrity, stable thermal behavior, and no performance-limiting degradation throughout the firing sequence. These are critical outcomes for propulsion engineers. Solid rocket motor components experience intense pressure spikes and rapid heat transfer. Meeting those loads without cracking or distortion is a high bar, especially for parts produced without melting or conventional forging.

Cold-spray additive manufacturing builds components by accelerating metal particles at supersonic speeds and bonding them through plastic deformation. The process avoids the thermal gradients found in laser-based AM, reducing residual stresses and enabling large, thick-walled structures with uniform properties. It also allows rapid deposition of material, which shortens manufacturing timelines and cuts waste—factors attractive to defense programs operating under urgent schedules.

Titomic notes that the thrust chamber was delivered within weeks, underscoring the speed advantages of cold-spray AM compared with traditional routes. The successful test strengthens the company’s position as primes look for faster, more flexible methods to produce propulsion hardware and reduce lead times across missile and launch-vehicle supply chains.

The result also aligns with broader Department of Defense interest in cold-spray technologies for both new builds and repair applications. Titomic is already working with another major U.S. contractor to evaluate cold-spray for rocket engine refurbishment, an area where the technology’s low-heat process could offer clear advantages.

With this milestone, Titomic Kinetic Fusion™ moves closer to operational deployment in propulsion programs. As demand for rapid manufacturing and localized production grows, cold-spray AM may become a key enabler for future missile and space systems that need stronger supply-chain resilience and faster turnaround from prototype to flight hardware.

Article & Image Source: Titomic