Download The Full Infographic HERE

Sterilization is a common role for lab ovens. Any product that touches humans or animals, such as medications, food, surgical instruments, and medical devices, must be sterilized. That stops the transmission of microbes from substances when consumed or administered to users Sterilization also protects some substances from decaying. But the heat you apply must be in touch with the item for a specific period. That being said, sterilization must be done quickly, efficiently, and, most importantly, cost-effectively. That’s where lab ovens can help.

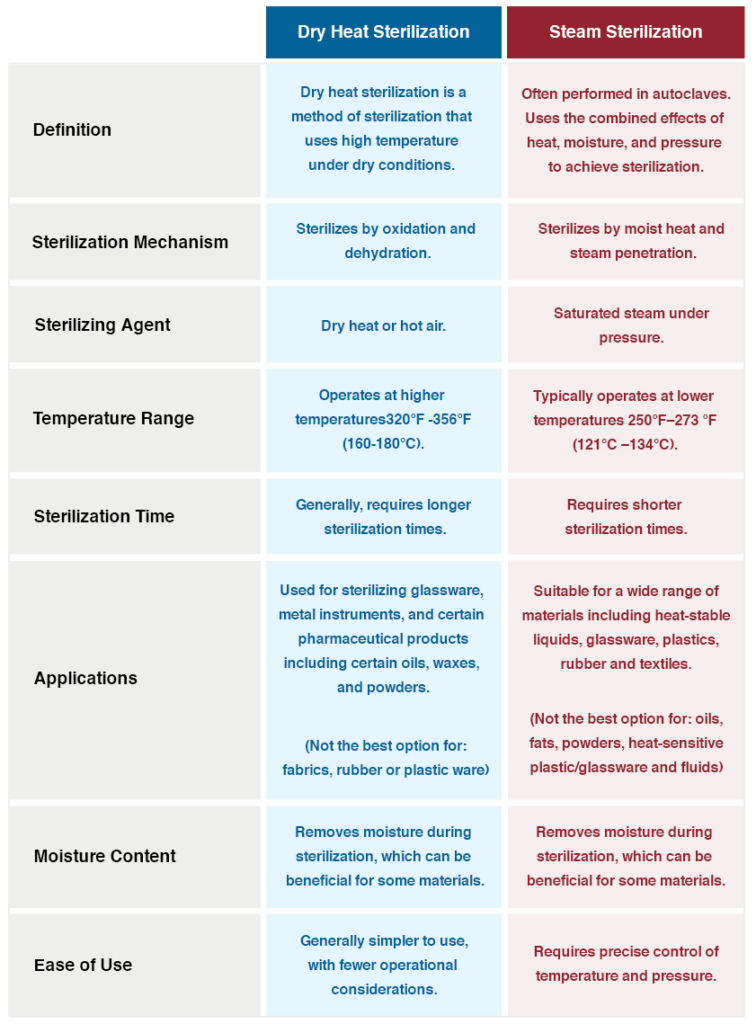

Lab ovens are proven sterilization systems. They can decontaminate all forms of viral and biological agents or deactivate them. Lab ovens are useful as sterilization systems in the medical, laboratory, biotechnology, scientific research, and pharmaceutical industries. They’re especially useful in the medical device manufacturing industry. Dry heating and steam heating are two effective methods of sterilizing items with lab ovens. Both use high temperatures to kill microorganisms on items, and both have distinct advantages. The critical difference is that steam heating sterilizers use moisture and dry heating sterilizers don’t.

What are Dry Heat Sterilization Ovens?

Dry heat sterilizers use heating elements to generate dry heat while keeping the chamber’s temperature high, usually between 160-180°C (320 OF -356 OF) for a specific time. Exposure time depends on what the item is. If the item allows, you can speed sterilization by raising the chamber’s temperature to 190 OC (374 OF) for 6 minutes or even a rapid 30-second heat up to 200 OC (392 OF). Once the required exposure time elapses, which generally takes about two hours, you can remove the items.

The heat passed onto the items causes the denaturation of proteins on all bacterial spores, fungi, viruses, prions, and other forms of biological agents. In other words, all living organisms die via oxidation. Some bacteria particularly resistant to heat can be destroyed or at least irreversibly deactivated when exposed to more intense dry heat. You can use dry heat sterilizers to decontaminate most metals, powders that can be compromised by moisture or chemical agents, anhydrous oils and fats, and glassware as well as paper-wrapped items and medical instruments of intricate geometry, such as (metal and glass) and surgical tools.

Pros and Cons of Dry Heat Sterilization

Advantages:

- Kills all organisms that steam heat can’t, including some types of prions resistant to moist heating.

- Goes deeply into thick objects, achieving in-depth sterilization and even inside packaging.

- Works on powders, metals, and oils.

- Doesn’t corrode metals since they contain almost no moisture. Metal objects that can handle heat well can be sterilized quickly at high temperatures.

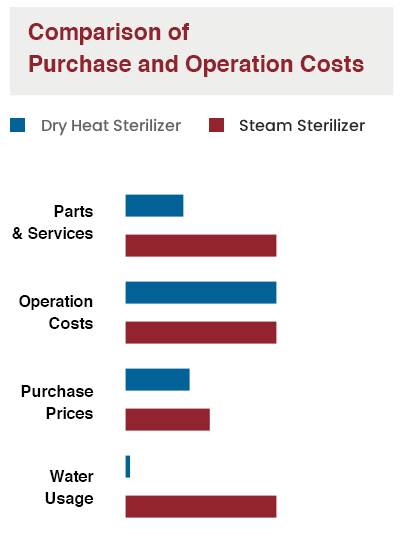

- Costs less to buy dry heat sterilizers. They’re also less complicated to use, cheaper to maintain, and minimizes operational costs.

- Involves no toxic agents in the sterilization process, so no harmful substances remain in the environment after using them.

- Cools down quickly, so you can remove items almost immediately after cycle is over.

- Needs no intervention during operation. Someone can set the oven and leave it to complete the cycle.

Disadvantages

- Takes longer to complete the sterilization cycle and requires higher temperatures, which increases costs because it consumes more energy for extended periods.

- Protects flammable materials that could combust and destroy heat-sensitive items.

There are two types of dry heat sterilizers—static air and forced air. Static-air sterilizers employ the principle of gravity convection. These sterilizers take longer to sterilize and reach the desired temperature, which is often inconsistent throughout the chamber. Forced-air sterilizers work on the principle of conduction. These sterilizers use their internal fans to blow hot air on the object. Thus, they achieve a more consistent temperature throughout the chamber. Forced-air sterilizers also deliver the heat load with better homogeneity than static-air ovens.

What are Steam Heat Sterilization Ovens?

Steam heat lab ovens, like dry heat lab ovens, expose the items to be sterilized to steam at high temperatures for a specified time. Steam heating often takes place in a pressurized autoclave, injecting steam at a temperature of 121–134 °C (250–273 °F) for 3 to 15 minutes at 103-110 kPa (15-16 PSI) onto the items. Once the ovens reach the required exposure time, the oven removes the steam and allows the user to extract the items from the unit. Boosting the temperature can shorten sterilization time.

Steam heat sterilizers subject bacteria, viruses, or other microorganisms on an item’s surface to steam. That, in turn, leads to hydrolysis and coagulation of proteins, killing microbes, viruses, and other microorganisms. While the amount of time required with steam heat sterilization depends on the item, these sterilizers are generally much quicker than dry heating. Steam heat sterilizers are also gentle on the items being sterilized. That reduces the risk of damaging sensitive materials. Steam heat sterilizers are typically used for devices and items composed of stable, heat-resistant materials, including rubber, metals, and durable plastics.

Pros and Cons of Steam Heat Sterilization

Advantages:

- Requires only a few minutes to complete steam heat cycle sterilization, so they cost less to carry out and boost lab productivity in the long term.

- Can sterilize liquids and flammable material by the moist heating of steam.

- Can penetrate dense samples, wrapped items, containers, tubes, and other hard-to-reach places.

- Coagulates the proteins in the living organisms during the steam heating process, killing all bacteria, spores, and fungi.

Disadvantages:

- Fails to achieve sterility on prions, bacteria, and mold spores that resist moist heating on some items no matter how high the temperature goes.

- Works poorly on materials that cannot tolerate moisture, including powders, anhydrous fats, oils, and metals that are not corrosion-resistant and/or can rust.

- Requires pressure vessels, nozzles, pits, exterior jackets, and so on. So, they cost more to acquire and maintain than dry heaters.

- Can damage some samples, items, and culture media, so it’s not applicable in all situations.

Put simply, dry heat sterilizers are less efficient than steam heat sterilizers and have lower initial costs, maintenance costs, and operational costs than steam heat sterilizers. Dry heat sterilizers are well-suited for fats, oils, and items that may corrode or be damaged by moisture, such as powders.

Steam heat sterilizers, on the other hand, are simple, safe, efficient, and cost-effective. They require less energy than dry heat sterilizers, boost productivity, and cut costs. Steam heat sterilizers are ideal for devices composed of stable, heat-resistant materials, including rubber, metals, and durable plastic materials.

Essential Factors When Buying a Lab Oven

Choosing the right lab oven for your application can be a challenge. But a knowledgeable oven manufacturer can help you select the correct oven. Below are some factors to keep in mind when buying an oven:

- Size/volume

- Temperature requirements

- Heating uniformity

- Airflow

- Energy consumption/efficiency

- Cleaning and maintenance

- Safety and reliability

Additional factors to consider when buying a lab oven include the items being sterilized, industry standards, company budget, cool-down times (by application), interior construction, heat-up rates, soak times, and type of design—batch or continuous processing.

Additional factors to consider when buying a lab oven include the items being sterilized, industry standards, company budget, cool-down times (by application), interior construction, heat-up rates, soak times, and type of design—batch or continuous processing.

Also, you should check the results of the oven’s temperature uniformity tests on the official product web pages, which many manufacturers publish. That will tell you something about the oven’s heating uniformity. Checking the oven’s certified test results will tell you more. If there are no test results, ask for a heating uniformity demonstration. A poorly heated lab oven can generate bad samples or contaminate products.

Chances are good a standard lab oven will work for you. That’s faster than buying a custom-engineered unit. You can also modify a standard oven to fit your application. To get a custom-engineered unit, however, you’ll need to work closely with the manufacturer to ensure you get the right oven.

Lab Ovens Are Invaluable

Lab ovens are invaluable sterilizing systems. Both steam heat and dry heat sterilization ovens play an important role in ensuring the safety and cleanliness of various products and materials, and they are essential for maintaining high standards of hygiene and cleanliness in various industries.

Dry heat sterilizers work by heating electrical coils situated at the chamber’s bottom, and then circulating the hot air throughout the chamber with fans. Two types of dry heat sterilizers exist—static air and forced air. Steam heat sterilizers work by injecting pressurized hot steam right onto the items to be sterilized. The lab oven then removes the hot air from the chamber.

Each sterilizer type has its advantages and disadvantages. Dry heating lab ovens are safe, proven, and cost-effective—whether forced air or static air. Options include HEPA filtration, inert atmosphere, Class A clean process capabilities, chamber size, and construction interior. Steam heating lab ovens are simple, rapid, and effective and the method of choice for many applications. These sterilizers use less energy, are more efficient, and cost less to operate and maintain than dry heat sterilizers. It’s critical you determine the type of lab oven that best fits your application.

Despatch offers a wide selection of sterilizing ovens that offer a range of chamber sizes and temperature capabilities. Please get in touch with us if you need more information about any of our ovens, from oven design and sales to installation and maintenance services.