A team of researchers at Northeastern University has developed a new class of plastic-ceramic composite that could help solve one of the most pressing challenges in modern electronics: heat management. Designed to efficiently conduct heat while remaining electrically insulating and lightweight, the material could reshape how consumer devices, radar systems, EVs, and even data centers handle rising thermal demands.

The composite — created through a precise combination of polymers, ceramic particles, and heat treatment — was developed by Professor Randall Erb and his team in the university’s Directed Assembly of Particles and Suspensions Lab. Their innovation addresses a key weakness in traditional plastics used in electronics: poor thermal conductivity. While previous attempts to embed ceramic particles into plastic offered some improvement, they often fell short of delivering the kind of performance required in today’s high-density devices.

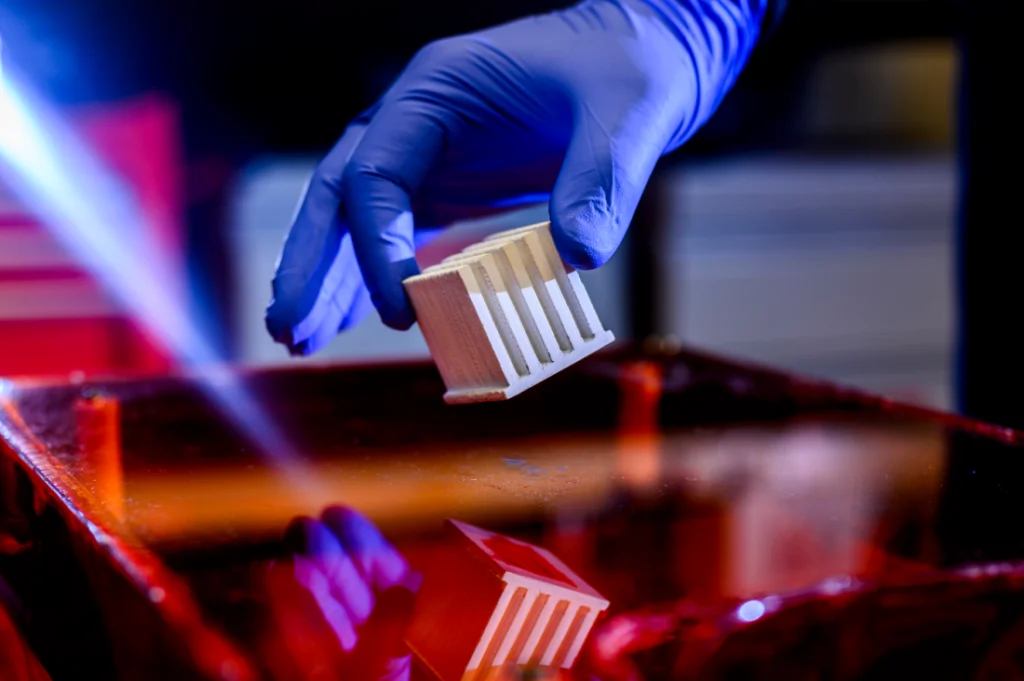

Erb’s team overcame this by designing a finely ordered internal structure. Through a tightly controlled 3D printing process and post-curing treatment, they were able to build microscopic crystalline polymer bridges that connect the ceramic particles, forming continuous pathways for heat to move quickly through the material. The result? A thermally conductive plastic that outperforms even stainless steel in heat transfer — yet is four times lighter.

This isn’t just a lab experiment. The material has been successfully fabricated in complex 3D shapes, opening the door to custom-fit thermal solutions for next-generation electronics. Just as important, it doesn’t conduct electricity, which means it can be used safely around circuits without the risk of shorting them out. And unlike metal enclosures, it won’t interfere with radio signals, making it ideal for use in 5G, radar, and other RF-heavy applications.

The implications are wide-ranging. It could help keep processors in smartphones and laptops running at full speed, even in hot environments. In data centers, it offers a new approach to handling the enormous heat loads generated by servers, potentially reducing cooling costs. For electric vehicles, the material may enhance battery safety by helping to disperse heat before it becomes dangerous.

The research team is now working with the U.S. Army Research Laboratory to scale up production, hinting at its potential for defense as well as commercial applications. As electronics continue to grow more powerful and compact, Northeastern’s new composite might just be what keeps them from melting under pressure.

Image & article source: Northeastern University