Biopharmaceuticals are revolutionizing how doctors treat diseases like diabetes, cancer, and rheumatoid arthritis. These drugs boost a clinician’s ability to treat specific medical problems. It’s hoped that someday they will be able to not only treat diseases but even cure them. For manufacturers, biopharmaceuticals (also known as biologics) can help take their companies to the next level of profitability. Overall, analysts expect biopharma to produce global revenues exceeding $163 billion.

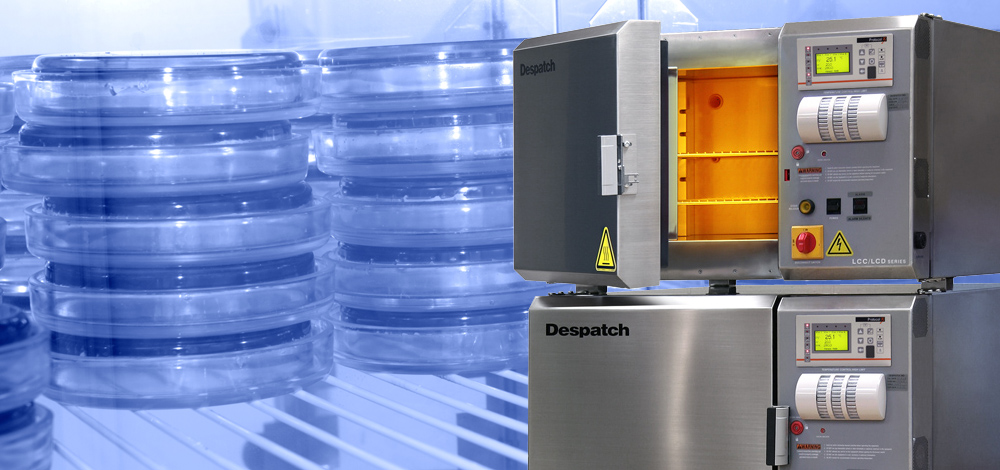

So, it’s no surprise that pharmaceutical manufacturers are looking to biopharmaceuticals to grow their businesses. But manufacturing these new drugs presents unique production challenges for traditional manufacturers. Overcoming these challenges takes expertise and reliable equipment, like the right lab ovens—the workhorses of many biopharmaceutical production processes. Versatile and reliable, lab ovens can drive efficiency by shortening cycle times, reducing rework, cutting downtime, and increasing yield/throughput.

What Are Biopharmaceuticals?

Biopharmaceutical definitions vary. Essentially, they’re large complex medications derived from living organisms. Blood plasma extracted from living systems is a biopharmaceutical you’re probably familiar with. Biopharmaceuticals are structurally identical to compounds already found in nature, like sugars, proteins, nucleic acids (DNA and RNA), or a combination of components. Manufacturers separate these components from living sources, such as humans, animals, plants, fungi, or microbes, and then use them as needed.

Biopharmaceuticals’ benefits are enormous. Simply put, they’re more effective than other treatments because they provide targeted treatment for diseases. They also have fewer side effects. Biologics include blood and blood components, cell therapies, therapeutic proteins, and vaccines produced using cells or viruses, depending on the type of vaccine you’re making. However, the best potential for biopharmaceuticals is gene therapy, which replaces ineffective genes with healthy ones to treat symptoms or prevent them from developing later.

Manufacturing Biopharmaceuticals Presents Challenges

Biopharmaceutical manufacturing, however, presents unique operational and technological production challenges. Generating the large molecules that some biologics require at an industrial scale, for example, is no picnic. This effort demands top-flight manufacturing equipment, which can be costly to acquire and use. Plus, biopharmaceutical manufacturers face long process durations, low yields, expensive raw materials, and a shortage of skilled workers. That all adds up in terms of dollars and cents.

One area of significant concern is energy consumption. The US Environmental Protection Agency (EPA) estimates that the energy consumption in a laboratory setting is five to ten times that of a typical office building. Biopharma manufacturers, for instance, often have processes running around the clock. That’s a lot of energy to consume daily. So, it behooves biopharma manufacturers to find ways to cut energy consumption. Using equipment that drives energy efficiency can help cut operating costs and increase competitiveness and profitability.

Using the Right Oven Boosts Energy Efficiency

Employing a lab oven with the right features increases energy efficiency. It also boosts productivity and profitability. Ideally, manufacturers want a lab oven that effectively uses chamber space. Too little or too much can drive up energy consumption and operating costs. Manufacturers also want an oven with high-quality insulation in the side walls, a shelving system that provides space advantages, door hinges and latches that prevent temperature loss, and the ability to control the oven with your computer. These features all help curb energy consumption.

Biopharma manufacturers can also curb energy consumption by using lab ovens that provide consistent, repeatable performance, shorten cycle times, and boost productivity. Plus, they want lab ovens that deliver the uniform and repeatable thermal processing required for critical biologics production efforts. Advanced electronics, like Despatch’s Protocol 3™, a microprocessor-based temperature and hi-limit controller, can help lab ovens operate flawlessly, ensure repeatable performance, and achieve superior product quality.

Biopharmaceuticals are revolutionizing how doctors treat many diseases, thanks mainly to the benefits they provide. Key benefits include pinpoint treatment and fewer side effects. But manufacturing biopharmaceuticals presents tough operational and technological challenges, including high energy consumption costs. Lab ovens can help manufacturers meet these challenges, but only if the unit has the right features. A Despatch lab oven with the right features, for example, can drive energy efficiency and cut operating costs. More important, it can increase competitiveness and take a company to the next level.

Want to know more about how Despatch lab ovens can boost efficiency in your pharmaceutical business? Then contact our technical team for assistance. We are here to help you maximize efficiency and achieve the highest quality standards possible.