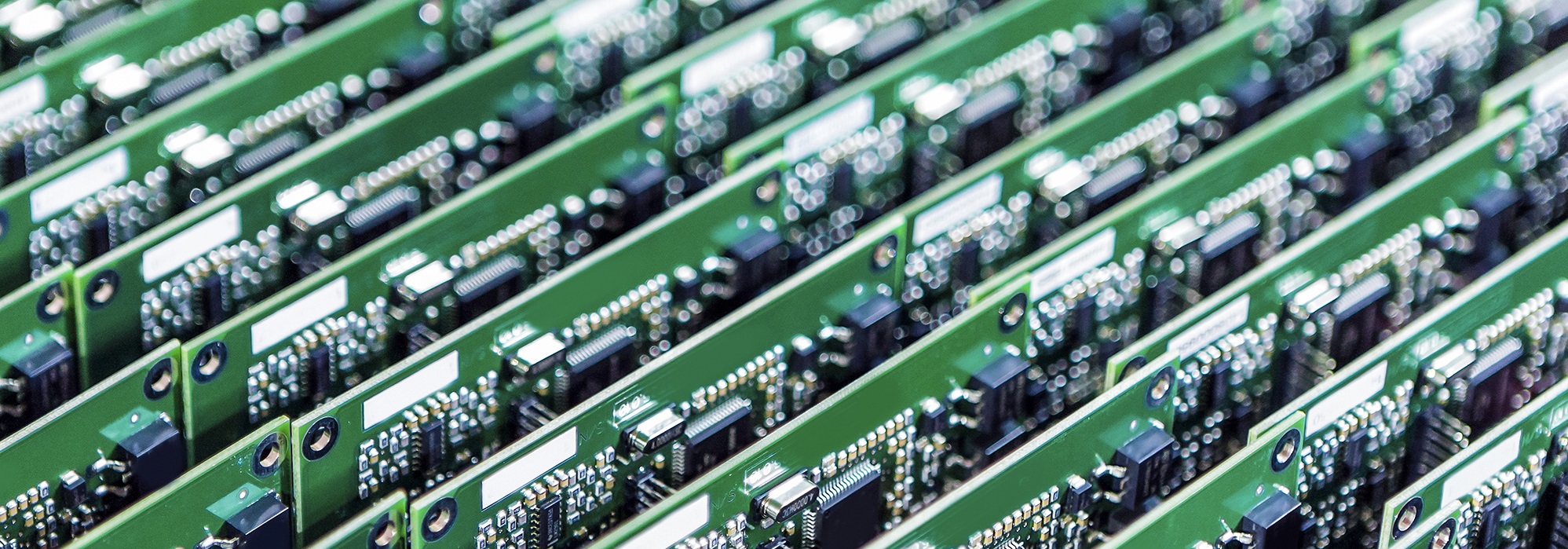

Failure of electronic components is very often a catastrophic occurrence, or at least a very costly one. Electronics are embedded on boards that incorporate tens or even hundreds of other components, so when something fails, it takes the whole part with it. Moreover, they are usually hard to reach, placed deep inside assemblies, and never meant to be serviced. Especially when these components support the operation of highly critical systems such as vehicle ABS units, life support medical equipment, railway signaling machines, and even space satellites, the importance of having reliable components hits the roof. Manufacturers and vendors know this very well, so they follow a wide range of tests to determine if their products are susceptible to any of the various failure modes that underpin electronics.

Causes for Failure of Electronics

When it comes to electronic components, there is are many possible causes of failure. The leading cause of problems is a packaging failure caused by thermal expansion, which leads to mechanical stresses and eventually a rupture. Another common failure mode is contact failures caused by excessive resistance heating. Printed Circuit Boards (PCB) are also vulnerable to certain chemicals, and heat is usually the cause of these chemicals leaking out onto the board in the first place. Relays are also susceptible to heat, as higher levels can drastically reduce their service lives.

Semiconductors and microchips can also fail due to nucleation, accumulation of charge carriers in the MOSFETs gate, improper passivation, and more. All of these causes see an increase in their probabilities at higher temperatures, suffering from higher leakage currents, lower signal to noise ratios (become more error-prone), loss of the properties of transistors, loss of cache memory, and even the breaking down of the crystalline structure of silicon. Capacitors and resistors also do not tolerate heat well, and higher temperatures minimize their service life. That said, the key element in testing electronics is to apply heat, and if there are any defects in the components, you will soon know about them.

Burn-In Testing

Using lab ovens, one could test electronic components with what is called “the burn-in test”. This test requires the component to operate continuously in its standard mode for an extended period of time, ranging from a couple of hours to a couple of days or even more. The humidity and temperature may be set by the researchers to meet the testing requirements, and the controlled environment of a lab oven chamber is ideal for this purpose. In most cases, defects become apparent within this short time frame.

Because some components are sensitive to oxidation, and as they are meant to be used in environments where there is no air, testing them without inducing oxidation can only be done by keeping the air (and thus the oxygen) out of the chamber, so some burn-in tests can only take place inside sealed lab oven chambers.

Thermal Stress Qualification Testing

Depending on the type and role of a component, as well as what operational conditions and periods you want to simulate, you may increase the temperature to a level that is beyond the component’s tolerance or expected value range, something that is called “heat soaking”. This is again practically achievable using a lab oven that can reach the desired temperature with precision and speeds up the process of testing an electronic component by inducing “infant mortality” types of failures.

Another type of thermal stress test is the “shock test” that puts the component over the ordeal of operating on temperature levels that change suddenly. For example, if you’re using your smartphone out in the cold at minus 10 degrees Celsius (15°F) and you suddenly enter the chalet which is a 20°C (68°F), is this going to damage the electronics on your device? Again, the only way to test this in a controlled environment and to also include the “sudden change” factor is by using a specialized lab oven that has features to support this purpose.

Despatch offers a wide selection of industrial ovens used to test electronic component. If you need more information about any of our Burn-In Ovens and Test Ovens, please contact us.