Boeing has unveiled a 3D-printed solar array substrate that compresses composite build times by up to six months from print to final assembly. This is an improvement the company equates to roughly a 50% production gain on a typical array wing program. The first flight hardware pairing these printed substrates with Spectrolab’s high-efficiency cells will ride on small satellites built by Millennium Space Systems, both Boeing subsidiaries. The goal is straightforward: shift space-power builds from artisanal timelines to repeatable, high-rate manufacturing that better suits constellation schedules.

What changes on the factory floor is the integration. Features such as harness paths and attachment points are printed directly into each panel, replacing dozens of separate parts, long-lead tooling, and delicate bonding steps with a single, rigid piece that’s faster to build and easier to integrate. That single-piece logic also allows for more parallel work streams. The panel prints while cells are processed, then robot-assisted assembly and automated inspection at Spectrolab cut handoffs and variability. As Boeing’s Michelle Parker put it, “Power sets the pace of a mission,” and the team’s intent is to turn production speed into a capability customers can plan around.

Boeing says flight-representative hardware has completed engineering testing and is progressing through its standard qualification path. The design scales from smallsats to Boeing 702-class platforms, with market availability targeted for 2026. Timed to coincide with several replenishment cycles now in planning. The company isn’t new to additive: across its portfolio it counts more than 150,000 3D-printed parts. These include over 1,000 RF components on each Wideband Global SATCOM satellite, and multiple small-sat product lines with fully printed structures. That enterprise base supports the solar array push and should help shorten the learning curve as volumes rise.

Lighter, stiffer, feature-rich substrates can reduce mass and assembly risk, accelerate panel integration, and open headroom for payloads without re-engineering downstream interfaces. For operators, faster arrays mean tighter schedules that hold. And for integrators, there’s the promise of fewer exceptions in assembly and integration. If early flights validate the factory gains, satellite builders get a clearer path to field resilient constellations.

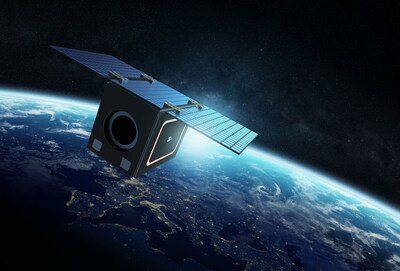

Image & article source: Boeing