Amkor is relocating its planned $2 billion advanced-packaging and test facility to a larger site in north Peoria, Arizona. City documents show the new, 100-plus-acre location gives Amkor more room for cleanrooms, support buildings, and future expansion. Construction is expected to begin soon, with production targeted for early 2028.

Why the move matters: advanced packaging is where chips get their brains and their brawn. Before a device ships, the package goes through a series of thermal steps, such as substrate drying, die-attach bake, underfill cure, post-mold cure, and a final bake-out to stabilize polymers. These steps are routine, but they’re also make-or-break for yield. A bigger site means more lines, better material flow, and space for the high-uniformity ovens and precise temperature profiles that those steps require.

Arizona is quickly becoming a semiconductor cluster, and Amkor’s plant anchors the OSAT (outsourced assembly and test) side of the ecosystem. With wafer fabs growing around Phoenix, keeping packaging nearby shortens logistics and cuts risk. That’s especially important for AI accelerators, automotive electronics, and other parts that see tight delivery windows.

For process and quality teams, the takeaway is straightforward. As package density climbs, ovens need to heat evenly across larger loads without overcooking sensitive adhesives and encapsulants. Good ramp/soak control reduces voids and outgassing before electrical tests. Facilities managers will also be watching energy use and cleanroom compatibility as lines scale.

There’s also a people and systems angle. New packaging capacity typically comes with recipe management and MES integration to lock down thermal profiles lot-by-lot, plus SPC dashboards to catch drift early. Expect local workforce pipelines, community colleges, and university programs to play a role in staffing operators, maintenance techs, and process engineers trained on thermal, wet, and test modules. The larger site should make it easier to stand up training labs alongside production.

What to watch next: supplier selections for substrates and adhesives; which product families run first (automotive, MCU, or 2.5D chiplets). Also, how local integrators kit wet benches, thermal tools, and handlers to meet 2028 ramps.

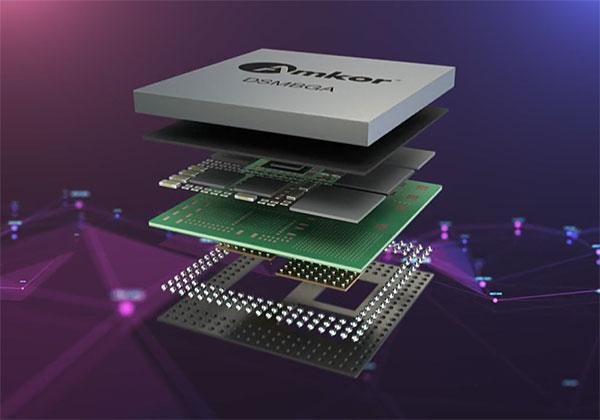

Article source & image source Amkor