Every thermal process carries some risk. But risks rises sharply when solvents or flammable vapors are involved. NFPA 86, the U.S. standard for ovens and furnaces, sets clear safety rules that reduce that risk.

When dealing with anything related to compliance, it is easy to focus only on passing an inspection. But compliance also improves safety, limits financial and legal risks, and keeps validated operations running. For QA leaders, it means ovens can prove they meet documented process requirements, which regulators in aerospace, medical devices, and semiconductors expect.

Background and scope of the NFPA 86 standard

The NFPA 86 standard for ovens and furnaces was created by the National Fire Protection Association, a US-based nonprofit. Technically, it is a US standard, but its influence is global.

Insurers, auditors, and multinational manufacturers often reference NFPA 86 as the accepted benchmark for oven safety, even in regions where local regulations also apply.

The standard covers everything from design and installation to operation and maintenance. It is updated every few years to include new technologies and lessons learned from industry incidents. This is important, because compliance is an ongoing responsibility tied to risk management and audit readiness.

Class A ovens and compliance risk

Four oven classes are defined by NFPA 86. But Class A ovens represent the higher-risk category.

These are ovens that are used for materials that release vapors or solvents that can ignite, as well as combustible dusts. Common examples include electronics coating, composite curing, and pharmaceutical drying, where residual solvents are a hazard.

The compliance risk comes down to two main areas:

- Explosion potential. A buildup of solvent inside the chamber can ignite if it isn’t properly vented.

- Audit failure. There must be documented proof that Class A ovens follow NFPA 86 requirements, including controls and maintenance records.

Make a mistake in either area and you could end up with production stoppages and costly recalls, and possible legal exposure.

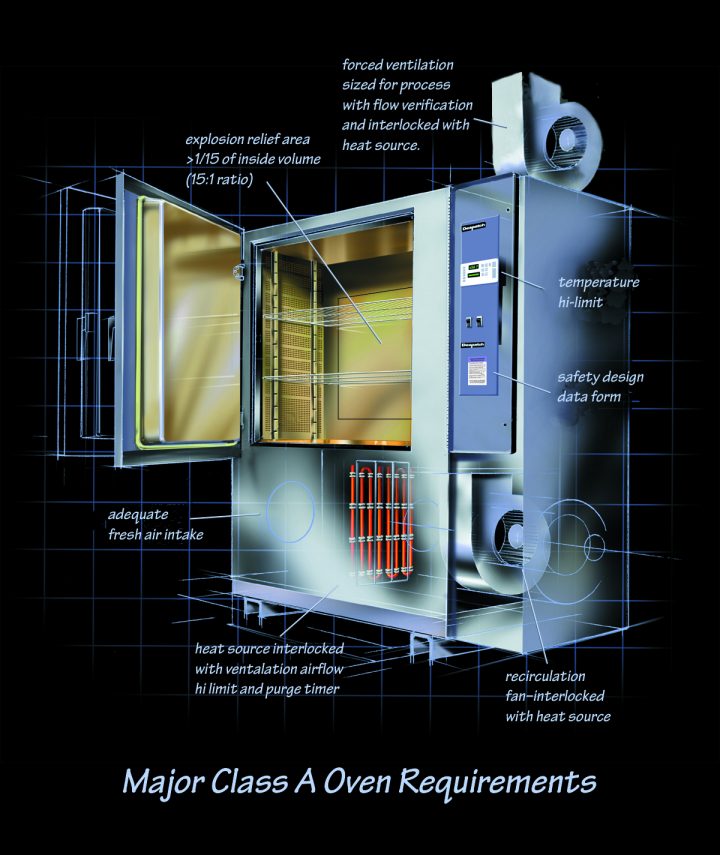

NFPA 86 requirements for Class A ovens

NFPA 86 outlines several requirements that are especially important for executives and QA readers to understand:

Exhaust venting

Class A ovens must be fitted with forced exhaust systems sized to maintain solvent concentrations below 25% of the Lower Flammable Limit (LFL) during operation. Correct sizing and monitoring are critical for safety and compliance.

Safety interlocks and controls

The standard requires interlocks that disable heat input if airflow is lost, dampers are closed, or solvent concentration rises above set thresholds. Interlocks should be regularly tested and documented as part of validation.

Purge cycles and monitoring

Before heating, ovens must complete a purge cycle that flushes the chamber with fresh air to remove residual vapors. Monitoring devices confirm airflow rates and purge timing. Modern Class A ovens include programmable controllers to automate these steps and record compliance data.

Documentation and inspections

NFPA 86 places heavy emphasis on recordkeeping. Companies must maintain installation reports, calibration certificates, interlock test logs, and inspection records. Annual third-party inspections are recommended, with in-house checks more frequent depending on process risk.

How to achieve compliance

For executives and QA teams, achieving NFPA 86 compliance follows a predictable sequence:

- Assessment — Identify whether your processes involve flammable volatiles. If they do, Class A ovens are mandatory.

- Specification — Define process requirements such as temperature range, load size, airflow, and exhaust capacity. Reference NFPA 86 clauses in procurement documents.

- Procurement — Choose a supplier with proven Class A configurations and documentation packages that support validation.

- Installation and validation — Confirm that exhaust ducting, interlocks, and purge systems are installed to specification. Run acceptance testing with documented results.

- Ongoing compliance — Schedule regular maintenance, calibration, and inspections. Keep a log of all interlock and purge cycle tests.

A structured approach allows for compliance to be built into the lifecycle of the oven rather than treated as a one-time exercise.

Mapping NFPA 86 requirements to Despatch models

| Use case / requirement | Despatch model families | Options supporting NFPA 86 compliance |

|---|---|---|

| Small-batch R&D with flammable solvents | LBB, LAC benchtop/cabinet ovens | Class A configuration with exhaust porting and airflow monitoring |

| Medium-volume production with solvent emissions | LAC cabinet ovens | Integrated Class A packages, airflow interlocks, LFL monitoring |

| Large-scale production or continuous processing | LCC clean process, conveyor ovens | Class A design with solvent-rated exhaust, programmable purge cycles |

| Validated cleanroom processing | LCC clean process ovens | ISO Class 5 HEPA filtration plus Class A exhaust and safety interlocks |

Compliance benefits for executives and QA leaders

Choosing ovens that meet NFPA 86 requirements comes with valuable long-term benefits:

- Regulatory assurance — documented compliance supports FDA, OSHA, and international audits.

- Risk control — reduces the likelihood of catastrophic incidents and protects workforce safety.

- Operational continuity — minimizes downtime and protects throughput in critical industries.

- Customer trust — demonstrates commitment to safe, validated manufacturing processes.

Compliance is both a safety requirement and a competitive advantage.

FAQs about NFPA 86 and Class A ovens

What is NFPA 86?

NFPA 86 is the National Fire Protection Association standard covering ovens and furnaces. It sets rules to prevent fires and explosions through design, venting, interlocks, and operational practices. The standard is widely recognized by insurers and auditors, so compliance protects manufacturers from liability, downtime, and failed safety or regulatory audits.

What makes an oven Class A?

A Class A oven is defined as one that processes materials releasing flammable vapors, solvents, or combustible dust in potentially hazardous concentrations. Industries such as aerospace, electronics, and pharmaceuticals often need Class A ovens. The classification ensures ovens have exhaust systems, interlocks, and purge cycles to reduce ignition risks during heating operations.

Are purge cycles mandatory for Class A ovens?

Yes. NFPA 86 requires purge cycles to flush the chamber with clean air before heating begins. Purging removes residual vapors that could ignite. Programmable controls can automate purge timing, airflow monitoring, and data logging, which also supports audit trails. Skipping purge steps or failing to record them places compliance and safety at risk.

How often should Class A ovens be inspected?

Class A ovens should undergo annual inspections by qualified third-party specialists to confirm compliance with NFPA 86. Most manufacturers also conduct quarterly or monthly in-house checks of interlocks, airflow monitors, and purge cycles. Regular calibration and recordkeeping are critical for passing audits and demonstrating due diligence to regulators and insurance providers.

Can Despatch supply documentation for audits?

Yes. Despatch provides installation reports, calibration certificates, and operation manuals with every Class A oven. Customers can also enroll in a Despatch service program to receive scheduled maintenance, inspection logs, and ongoing compliance support. This documentation package helps QA managers maintain audit readiness and demonstrate adherence to NFPA 86 oven standards.

Review your process requirements and NFPA 86 obligations. Then contact us or one of our product specialists to decide which Class A oven configuration is right for your production line.