Metal additive manufacturing has a new twist, literally. A student team at ETH Zürich built a laser powder bed fusion system that prints on a rotating platform, depositing and fusing powder in one continuous motion. The circular tool path cuts dead time between layers and, crucially, enables simultaneous processing of two different metals in a single build. This could be a real productivity gain for aerospace components with ring-like geometries.

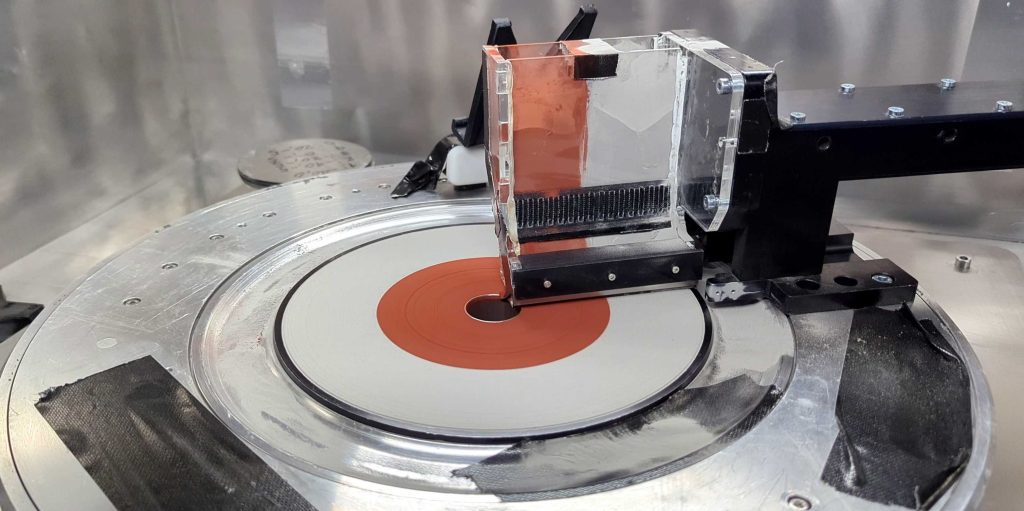

The prototype emerged in nine months in ETH’s Advanced Manufacturing Lab under Prof. Markus Bambach and Senior Scientist Michael Tucker as part of the RAPTURE focus project. The team is targeting applications such as rocket nozzles and turbomachinery, where a copper interior (for thermal conductivity) and a nickel alloy exterior (for heat resistance) make engineering sense but have been cumbersome to manufacture. With the rotating architecture, the printer reduces wasted mixed powder by applying material only where needed and uses tightly controlled inert gas flow to stabilize melt pools.

ETH has filed a patent application covering this rotary multi-material LPBF technology. Early parts include a 75-mm diameter turbine stator, and the group is now exploring larger diameters and higher speeds. The promise is twofold: faster throughput for cylindrical parts and new material combinations that were impractical with traditional rectilinear recoating. If the process scales, expect interest from propulsion startups and turbine OEMs that already rely on AM but need better economics.

The broader implication is access. Student rocketry teams, such as Switzerland’s ARIS, stand to benefit if they can produce bi-metallic nozzles without outsourcing exotic processes. That shortens iteration cycles. It also spreads competence as more engineers learn to design for multi-metal structures from the start.

As always, proof will come from repeatability, qualification data, and material properties at scale. But the core idea (continuous rotation to keep the laser printing while powder flows) resets the tempo for specific geometries. And it shows how a lean team, focused on a clear use case, can push AM beyond incremental tweaks.

Image & article source: ETH Zürich