Is your company looking for a NADCAP composite curing ovens that won’t trip you up at audit time? This guide outlines how aerospace manufacturers can meet stringent NADCAP standards, select compliant equipment, and enable a Continuous aerospace composite curing process that passes audits on the first attempt.

Despatch has built industrial ovens since 1902 and works with leading aerospace manufacturers, so the insights below reflect real audit expectations and shop‑floor realities.

What is NADCAP and Why it Matters for Aerospace Suppliers?

NADCAP (administered by PRI) is the aerospace industry’s consensus programme for special‑process accreditation. Instead of every OEM auditing you separately, a single PRI audit verifies that your process and equipment meet agreed criteria—often a contractual requirement for flight hardware. Start at PRI’s official NADCAP page, and use eAuditNet’s Qualified Manufacturers List (QML) to benchmark what accredited peers are doing.

Key Oven Requirements to Meet AMS2750 Pyrometry Requirements

- Pyrometry discipline (AMS2750): Auditors check for AMS2750 pyrometry requirements—covering SAT, TUS, and sensor calibration. Expect documented controls for temperature sensors, instrumentation classes, System Accuracy Tests (SAT), and Temperature Uniformity Surveys (TUS). AMS2750H (current) outlines these core elements and their intervals. Build your URS to reflect your OEM and Task Group expectations.

- Temperature uniformity: Define your required band across the work zone at relevant set‑points. Uniformity underpins void‑free laminates and repeatable resin cures. (Your OEM spec—e.g., BAC5621—may tighten uniformity and mapping rules.)

- Traceable data logging: Auditors will look for complete, tamper‑evident records—setpoints, actuals, SAT/TUS results, and batch identifiers—exportable for review. PRI training materials emphasise this record‑keeping for audit success.

- Vacuum integrity and control (for OOA/VBO): Out‑of‑autoclave curing uses vacuum bag‑only consolidation in a controlled oven. Specify stable vacuum with continuous monitoring and alarms over the full cure cycle.

Oven Features That Enable NADCAP-Compliant Aerospace Composite Curing

Map the requirements above to concrete features when you evaluate equipment:

- Airflow engineered for composites: Uniflow or custom airflow promotes even heat transfer to complex tools and lay‑ups, driving uniformity during ramps, soaks and cools.

- Integrated vacuum bagging systems: Multi‑port vacuum manifolds and jack panels support multiple parts and thermocouples with stable, logged vacuum throughout the cycle.

- Audit‑ready controls and reporting: A PC‑based process controller that sequences recipes, enforces limits, and auto‑generates batch reports simplifies NADCAP evidence collection.

- Walk‑in capacity for real parts: Walk-in ovens for aerospace components sized for full assemblies help you achieve uniform curing. Furthermore, they reduce the risk associated with piecemeal processing.

- Out of autoclave (OOA) composite curing capability: Has gained traction for cost efficiency while still meeting NADCAP compliant industrial oven requirements.

Questions to Ask Before Buying NADCAP Compliant Industrial Ovens

- Uniformity guarantee: What uniformity can you guarantee across my defined load volume and set‑points? Will you perform a witnessed TUS to confirm?

- Pyrometry alignment: How does the control/instrumentation package support AMS2750 (sensor types, instrument classes, SAT/TUS workflows)?

- Calibration & traceability: Are calibrations and SAT/TUS services available with ISO/IEC 17025 accreditation where required by my spec/OEM?

- Vacuum system details: How many vacuum/pressure ports per wall, monitoring resolution, allowable leak rate, and stability over multi‑hour cures?

- Data & reporting: Can I export encrypted, review‑ready batch reports with thermocouple maps, alarms, and operator actions?

- Scalability & service: How quickly can capacity expand (additional ports, TC channels), and what global service coverage is available?

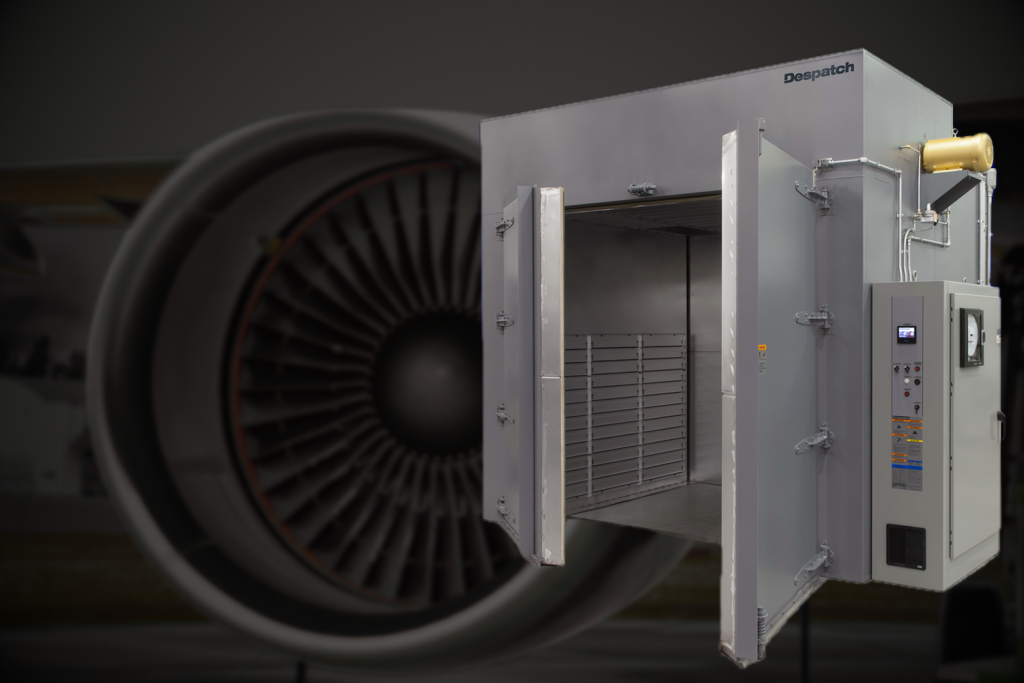

Despatch Walk-In Ovens for Aerospace Composite Curing

Despatch’s composite curing ovens pair a custom walk-in design with multi-port vacuum systems and Focal Point™ controls. The result? Tight temperature uniformity, full data traceability and NADCAP-ready performance.

Our TAD/TFD walk-in ovens handle large aerospace components with engineered airflow for consistent curing. For high-mix out-of-autoclave (OOA) work, Despatch configures TFD models with multiple thermocouple jacks, vacuum and pressure ports, all seamlessly managed by Focal Point™.

FAQs: NADCAP Ovens for Aerospace

1. What does NADCAP require for composite curing ovens?

NADCAP audits verify pyrometry compliance (AMS2750), temperature uniformity, vacuum control, and full traceable data logs.

2. What is the difference between an autoclave and an out-of-autoclave (OOA) oven?

Autoclaves combine heat and high pressure; OOA ovens use controlled heat and vacuum bagging, reducing cost and complexity.

3. How often are Temperature Uniformity Surveys (TUS) required?

Intervals depend on oven class and OEM spec, but audits typically require quarterly to semi-annual TUS per AMS2750.

4. Why choose Despatch for NADCAP-compliant ovens?

Despatch ovens offer engineered airflow, integrated vacuum, audit-ready controls, and global service trusted by leading aerospace OEMs.

Partner with Despatch for Your Aerospace Application

Guarantee your next NADCAP audit is a success. Explore our NADCAP compliant industrial ovens designed for aerospace applications or speak with an application specialist. Learn more about Despatch and our century‑long track record serving regulated industries.