A lesser-known but rapidly emerging technology – Photonic Curing – is reshaping how manufacturers process thin-film and printed electronics materials. Unlike traditional ovens that rely on prolonged heat exposure, photonic curing uses intense, pulsed light to achieve high-temperature effects in mere milliseconds, offering unprecedented throughput, energy efficiency, and product quality.

What Is Photonic Curing?

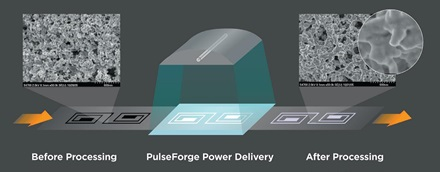

Photonic Curing applies short bursts of light – typically from flashlamps – generating extremely high temperatures for a fraction of a second. This allows processing of temperature-sensitive substrates like plastics or flexible films without causing damage. The method has shown exceptionally fast curing speeds and precise control, ideal for applications such as printed circuit boards, sensors, and emerging flexible electronics.

Why This Matters for Industrial Oven Users

Remarkable speed and throughput: Curing time is reduced from minutes to milliseconds, offering a quantum leap in production speeds.

Substrate protection: Delivers high-temperature outcomes while preserving delicate materials – something conventional ovens struggle with.

Smaller footprint, lower energy use: Compact systems consume minimal energy compared to full-scale thermal ovens, making this technique greener and potentially more cost-effective.

Integration potential: Ideal as a rapid supplemental step within broader thermal processing – not a replacement – in hybrid production systems.

Real-World Application & Market Relevance

Photonic curing is already proving its viability in printed electronics, where manufacturers require efficient thermal treatment of conductive inks and coatings on flexible or low-temperature substrates. It’s a breakthrough for industries like wearable electronics, solar films, and RFID tagging, where traditional thermal systems are either unsuitable or inefficient.

Strategic Relevance for you and your company?

Despatch Industrial Ovens excels in delivering precision, uniformity, and energy-efficient thermal solutions. By staying ahead of innovations like photonic curing, you can work with Despatch to explore hybrid systems that combine traditional batch or continuous ovens with targeted photonic modules. Such hybrid solutions could offer the best of both worlds: the consistency of established thermal ovens and the rapid, substrate-friendly capabilities of photonic processing.