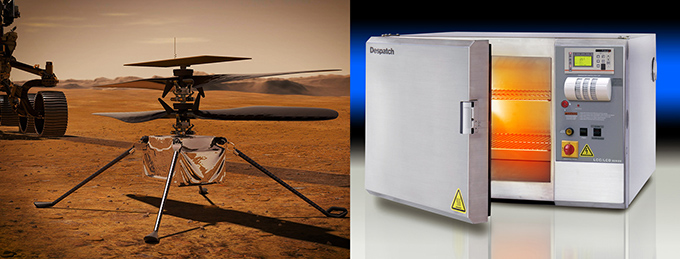

Class A LAB OVEN for NASA Space Center

The NASA Goddard Space Flight Center needed an oven cure epoxy adhesive. Development of mission critical technology requires a high degree of certainty that equipment will perform as specified. They trusted the Despatch LCC1-51 cleanroom oven to deliver the uniform and repeatable thermal processing required for critical components to operate flawlessly in space, where failure is definitely not an option.

The main adhesives they use are 3M Scotch-Weld 2216 Gray, EPO-TEK T7110, and EPO-TEK H74. For high strength structural bonds, paint, oxide films, oils, dust, mold release agents and all other surface contaminants must be completely removed. Parts are cleaned with Isopropyl alcohol and sometimes ethanol to prepare for bonding which are then dried in the oven. Once cleaned, epoxy is applied and then cured in the oven at 200°C. Given the solvents involved in these processes, a Class A package with an explosion relief panel, airflow switches and a purge timer was required.

NASA also requested that the oven be silicone free to meet Class 100 cleanroom requirements. The presence of silicone can create problems for some applications where trace amounts of silicone in thermal processes will prevent necessary adhesion in later process steps. The silicone door seal is replaced with a Viton seal and non-silicone-based sealants are used.