Do you process flammable solvents or products with combustible vapors at your company?

If you do and you’re not using a Class A oven that meets NFPA 86 Standards, you’re courting disaster.

Failing to use a Class A oven when required increases the chances of a life-threatening industrial accident, which can cost you big time, these industrial accidents don’t just happen. They’re caused by something. Inadequate training of Class A oven operators, lack of proper oven maintenance, improper application of equipment, taking shortcuts and neglecting safety features—any of these things can cause an accident that could shrink your company’s profitability. So, can using the wrong oven to process volatiles at your company.

What’s A Class A Oven?

Class A ovens are used when processing volatiles that could explode or cause a fire.

According to the National Fire and Protection Agency’s (NFPA) Standard for Ovens and Furnaces, Class A ovens are: “Heat utilization equipment operating at approximately atmospheric pressure wherein there is potential explosion or fire hazard that could be occasioned by the presence of flammable volatiles or combustible materials processed or heated in the furnace.”

If you process a flammable product or remove combustible vapors from a product in an oven, you will need a Class A oven that meets NFPA 86 requirements. Flammable volatiles that pose a potential explosion or fire hazard can originate from paints, powders, inks, and adhesives from finishing processes, such as dipped, coated, sprayed, and impregnated materials and from polymerization or other molecular rearrangements. Combustible materials include substrate material, wood, paper, plastic pallets, spacers, and packaging materials.

Because a Class A oven is used in industries that process a combustible product or remove combustible vapors from a product in the oven, it is important to understand its definition and function. See NFPA 86 Standard for Ovens and Furnaces, 2019 Edition(www.nfpa.org), for the latest safeguards required to minimize explosion hazards from the National Fire Protection Association. Understanding and complying with these National Fire Protection guidelines helps ensure the long-term safe operation of ovens that are either fuel-fired or process combustible or flammable solvent material.

Despatch incorporates all pertinent NFPA required safety testing, visual inspection and required documentation in all Preventative Maintenance and Calibration Service Agreements.

Key Features of Class A Ovens

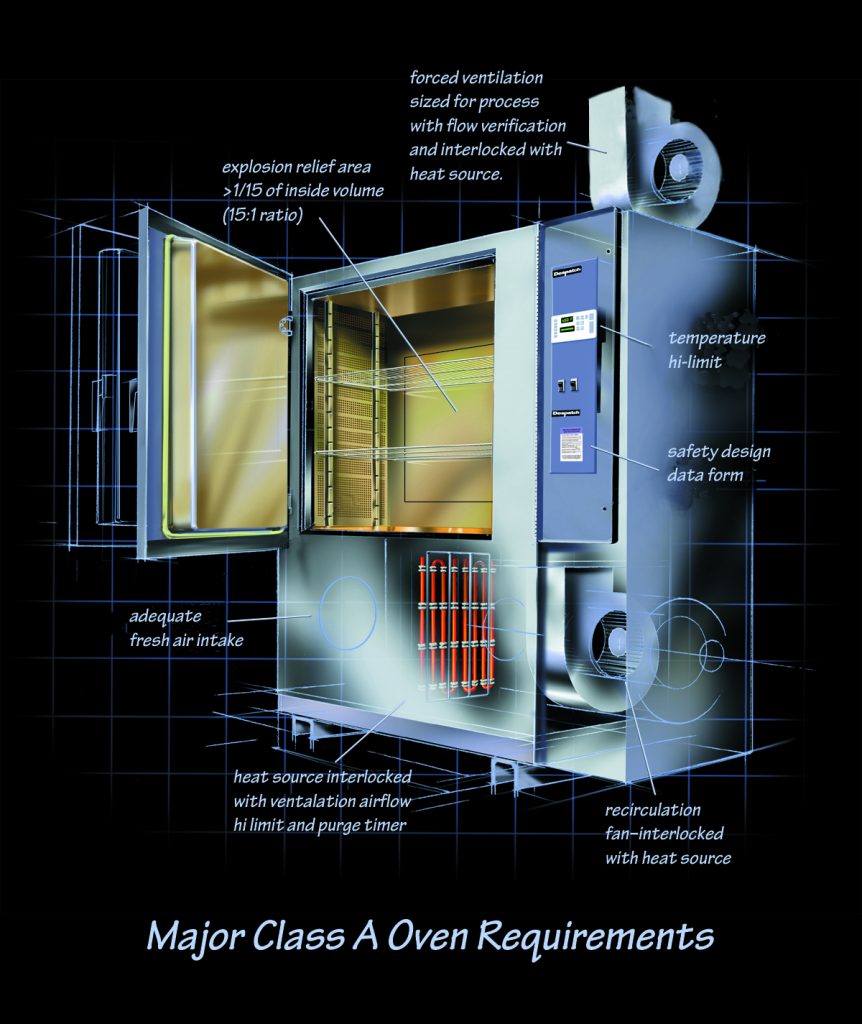

Figure 1.

Class A ovens are designed specifically for volatile applications and have critical features Class B ovens don’t have. So, you must be aware of these critical features of Class A ovens and how they impact the application. These features include:

- Forced heat ventilation interlocked with the heat source

- Explosion relief area with a specific inside volume

- Adequate fresh air intake

- Heat source interlocked with ventilation airflow

- Hi-limit and purge timer

- Recirculation fan interlocked with the heat source

- Excess temperature controller with hi-limit

In addition to these features, you must attach a completed safety design data form to the oven if solvent atmospheres are present. The form must include the solvent quantity per hour or batch, purge time, operating temperature, and exhaust rating.

NFPA 86 Requirements for Class A Ovens

NFPA 86 has requirements for annual inspection, operational testing, documentation of testing, and visual inspection of specific oven components, including:

- Safety interlocks

- Setpoint of temperature, pressure, and flow devices used as safety interlocks.

- Pressure and explosion relief panels

- Gas heater components

When purchasing Class A ovens, you will need to consider process or solvent type along with a Material Safety Data Sheet (MSDS) on the solvent, the amount per batch per hour, the temperature profile including maximum temperature and time to temperature, and information on solvent release time if available.

Despatch incorporates all pertinent NFPA-required safety testing, visual inspection, and required documentation in all Preventative Maintenance and Calibration Service Agreements for its Class A Ovens.

Figure 2.

Best Practices for Class A Ovens

Below are several considerations to keep in mind when buying or working with Class A ovens and processing volatiles:

- Class A ovens must have an explosion-relief area where the interior cubic volume of the oven is equal to at least one-fifteenth of the interior volume, or a 15:1 volume-to-venting-area ratio. For example, an oven with a total volume of 45 ft. 3 in. needs to have at least 3 ft. 2 in. of vent area.

- Class A ovens must have ventilation size that can accommodate the amount of combustible product in the maximum oven load. The typical ventilation requirement for a solvent-drying batch oven must be sufficient to render the average vapor concentration below 10 percent of the lower flammable limit if you operate the oven at 250°F (121°C) or below. If you operate the oven between 250 to 500°F (121 to 260°C), that ratio increases, and a 14:1 ratio is required.

- Above 500°F, you must address special considerations to determine the ventilation ratio. The reason for the high ventilation requirements is the high rate of initial solvent released when you place a batch of parts in a hot oven. Continuous ovens require a lower 4:1 ratio because the product is fed at a constant rate, producing much smaller peaks in solvent vaporization.

- Class A ovens must have a purge period before the heat source can be energized. This purge period must be long enough to get at least four air changes of interior volume. An oven with an interior volume of 100 ft3 and exhaust ventilation of 125 ft3/min would require 3.2 min purge time (100 ft3 x 4 = 400/125 = 3.2 min).

- The exhaust ventilation of the oven must be proven before powering the heat source. This oven requires an airflow switch or other means of verifying the exhaust. The exhaust and recirculation fan motors must be electrically interlocked to prevent the heat source from being energized if the fan motors are not running.

In addition to these requirements, operators must be trained to understand the equipment’s ratings and how they relate to the product being processed.

The environment in which the oven resides tempers all of the above requirements. Class A ovens without additional modification are not usable in hazardous atmosphere areas such as those requiring Class 1, Group D electrical construction. If they are to be utilized in hazardous areas, additional safety precautions spelled out by the National Electric Code must be met.

Finally, the complete definition, including the calculations required for determining exhaust ventilation rates for different volatile solvents, is contained in NFPA 86 Standard for Ovens and Furnaces. When dealing with volatile substances, it’s better to be safe than sorry. Even a minor industrial accident can cost your company dearly.

Still confused about buying a Class A industrial oven? Let us help? Contact your Despatch Sales Representative for more information at www.despatch.com.

Figure 1. A typical safety design data form outlines the operating parameters of Class A ovens operating with solvent atmospheres.

Figure 2. Class A oven design guidelines dictate that several features must be included in the oven design