Sublime Systems, a company developing a clean cement-making process, has said that they are ready to scale production on their “true zero carbon” cement.

Cement is necessary for making concrete, which is foundational in construction and infrastructure around the globe because it’s cheap, strong, and durable. Cement powder is conventionally made by crushing raw materials, including limestone and clay, mixing them with other elements such as iron and fly ash, then heating it all at about 2,700 degrees Fahrenheit.

This process generates approximately 8% of global carbon dioxide emissions, a leading cause of global warming.

A Revolution in the Cement Manufacturing Process

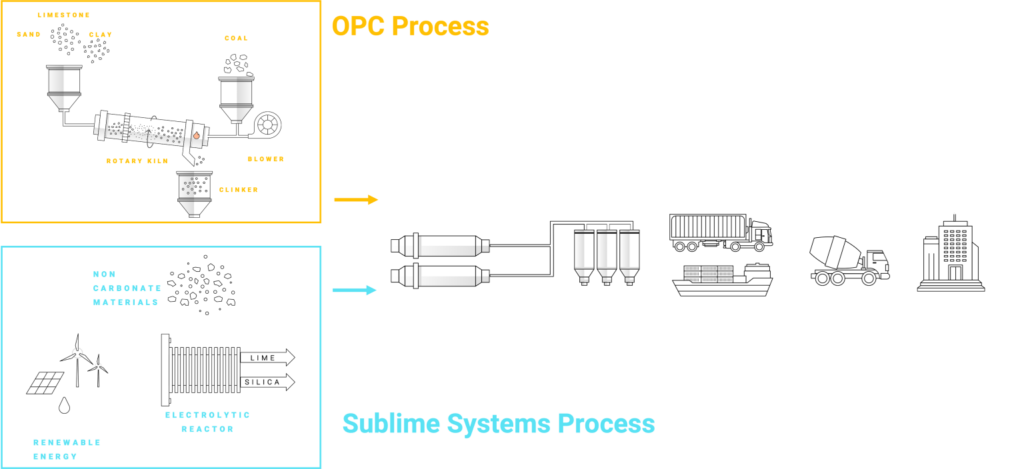

Although there is no shortage of low-carbon and carbon-capturing concrete alternatives in the works, Sublime’s approach is completely different, which is based on electrolysis. It uses an electrochemical technology to make cement that’s “true zero carbon” instead of “net zero carbon” or “carbon-sequestering” processes. As a result, it can remarkably eliminate carbon emissions.

In this process, water is split at near-neutral pH to produce hydrogen and oxygen gasses. A calcium-bearing mineral reacts with the acid formed at the anode to create dissolved calcium ions, which then migrate toward the cathode.

They react with the base generated at the cathode to precipitate out as solid calcium hydroxide, also known as builder’s lime or slaked lime, when they reach a pH of at least 12.5. This lime is a replacement for traditional cement manufacturing.

The Future of True Zero Carbon Cement

The traditional concrete manufacturing process results in a ton of CO2 for every ton of cement produced, therefore, a cost-competitive, totally zero-carbon cement alternative could bring many benefits not only for the environment but also for manufacturers as decarbonization mandates and carbon taxes start to kick in.

Sublime announced that its product has attained ASTM C1157 designation, which means Sublime Cement can now be used in compliance with major American and international building codes. Sublime has spun out and scaled up considerably since its establishment as a gram-scale research lab model at MIT. According to the company, their process is scaled up and the technology is mature. For now, the business can make on the order of 100 tons per year of cement.

Article Source: Interesting Engineering

Images from: Sublime Systems