A team of engineers at American universities has presented a new kind of chemical process that can completely strip ammonia out of industrial wastewater and polluted groundwater. The method is so effective that if combined with secondary treatment steps targeting other contaminants, it would clean the wastewater to the point of making it drinkable.

What’s more important is that the retrieved solid ammonia may then be used as a fertilizer on crops, recycling the precious substance that is otherwise produced through an energy-intensive and environment-harming process. The world needs an annual supply of over 170 tons of ammonia, and the sanctions imposed against Russia, one of the most significant producers of the substance, have created a shortage. Global ammonia production accounts for 1.4% of the world’s annual CO2 emissions, so it is a significant problem.

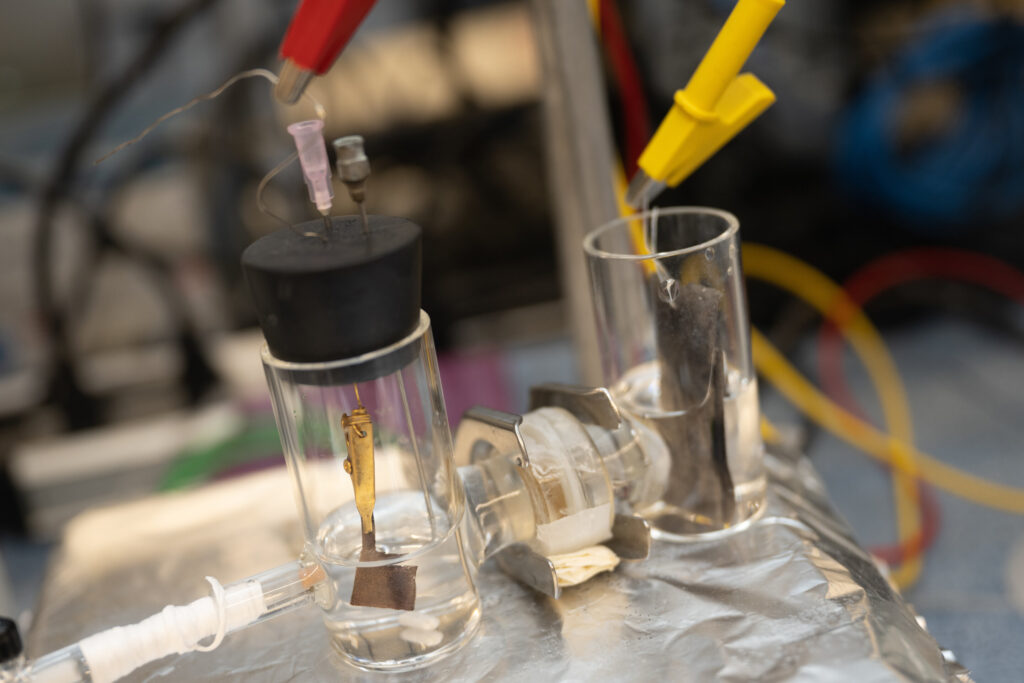

The key to the new process is combining copper with ruthenium in a precisely balanced mix that would help catalyze the wastewater when combined with a small amount of electricity. The team accomplished that by dispersing single ruthenium atoms into a copper matrix. When there’s too much ruthenium, the water gets in the way. When there’s too much copper, not enough hydrogen atoms are generated for the chemical path to complete. The scientists figured out the correct dosage through experimentation and density functional theory calculations.

This new chemical process is suitable for industrial-scale applications. Its cost is relatively low, it doesn’t need a large infrastructure, and the electric current (1 amp per square meter) is within the manageable range for all modern industrial plants. Also, the process works at room temperature and standard atmospheric pressure, so there are no special requirements on that front either. Particularly in places like high nitrate sources, this process would make much sense from an economic perspective, so this is where the developing team focuses next.

Article & Image Source: Rice University