If you’re a manufacturer with a cleanroom environment, “silicone contamination” are two words you never want to hear. Notorious for causing materials to separate from surfaces, silicone contamination leads to derailing manufacturing/assembly operations, delaying deliveries, driving up production costs, and bonding failures, which can saddle you with quality issues. Silicone contamination spreads through a manufacturing facility through physical contact with materials and equipment or by the air stream. A silicone-free industrial oven can be your best option to prevent cross-contamination in cleanrooms.

Contamination generates significant risks for manufacturers. Contamination in cleanrooms can lead to contaminated products, which may bring about problems you want to avoid, such as product recalls, regulatory sanctions, fines, fees, and damage to your reputation. With detection and removal costly and challenging, proactivity is the most cost-effective approach to preventing silicone contamination—a critical concern in industries like electronics, pharmaceuticals, biomedical, microelectronics, nanotechnology, and aerospace. Even small amounts of contamination can wreak havoc in a cleanroom manufacturing environment.

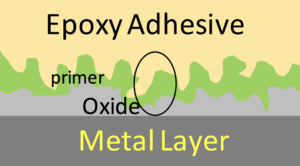

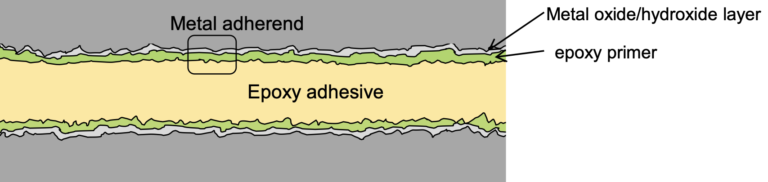

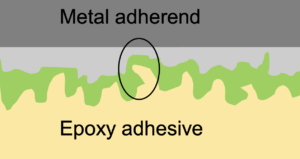

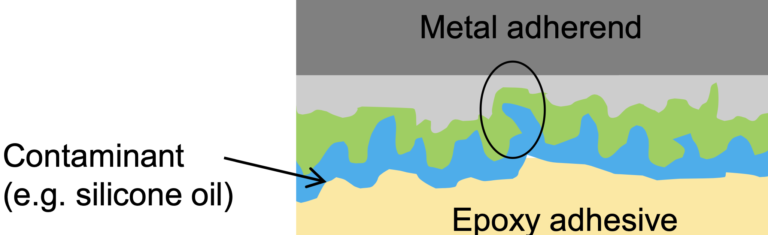

Figure 1: This figure shows how silicone is used in a typical application and the threat posed by the contamination. Silicone contamination can interfere with the key bonding mechanisms by acting as an interstitial and blocking contact locations for physical dovetailing or chemical bonding.

Silicone Contamination is Insidious

Silicones are versatile and popular materials. You can use them in lubricants, adhesives, films, barriers, and as process additives. Silicones can help adhesion on a product’s surface—thanks to their unique combination of physical and chemical characteristics. Plus, they have extremely low surface energy, so they wet most surfaces well. They’re ideal for many manufacturing and assembly applications, so going silicone-free may not be practical. In the pharmaceutical industry, for instance, silicone is used as part of many formulations and in manufacturing and packaging.

Manufacturers, however, need to be careful when using silicone. It can lead to silicone contamination, which can spread through contact or even through the air. Plus, contamination is hard to identify and remove. Sources of silicone contamination in manufacturing facilities are plentiful. They include cosmetics, hand lotions, mold releases, and lubricants on manufacturing equipment. They also include silicone-based adhesives, sealants, films, off-gassing during cures of silicone paste adhesives, and residue from pressure-sensitive tape.

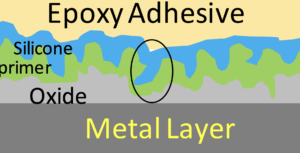

Figure 2: This graphic illustrates how silicone oil can impact adhesion by lowering surface energy and creating a structurally weak boundary layer between the adhesive and adherend’s surface.

Silicone Contamination: A Persistent Concern

Silicone contamination is a persistent concern in a wide variety of applications. Many food, drug, and cosmetic applications, for example, require 10 ppm or less silicone levels. It is also a persistent concern in many semiconductor, electronics, and microelectronics applications. It can cause severe problems in device performance and reliability. Once inside a digital device, silicone contamination can cause defects such as increased leakage currents, decreased breakdown voltages, and reduced reliability.

Silicone contamination is also a concern in bonding and sealing in assembly processes. It prevents direct contact between the adhesive and the product. This disorder is among the most prevalent causes of contamination on the manufacturing floor. One source says it accounts for more than one-third of the bonding problems occurring in aerospace production plants. And it doesn’t take much for a problem to occur. A one-half monolayer of silicone coverage on a surface is enough to cause a critical reduction in the bond strength.

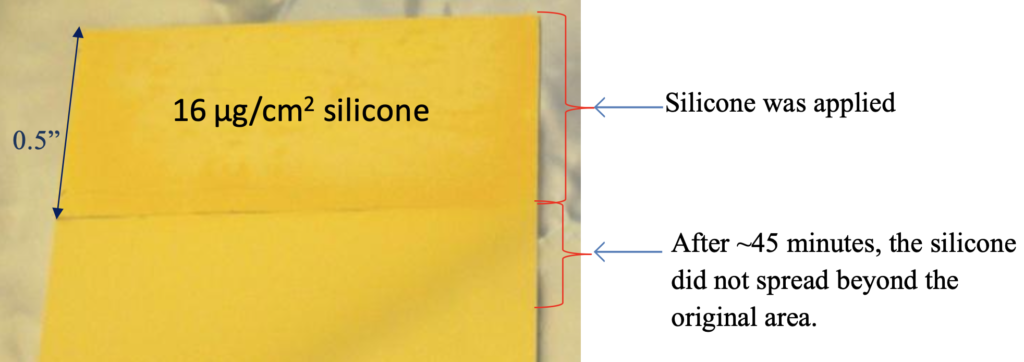

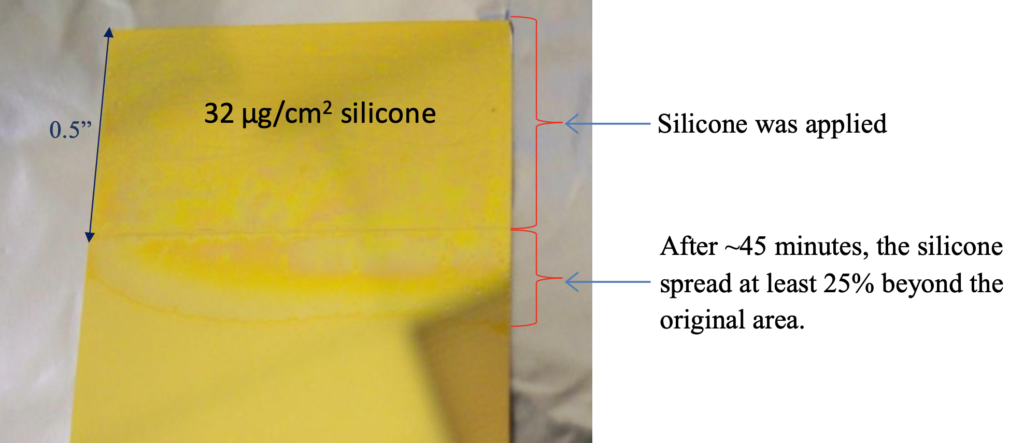

Figure 3: This figure shows how insidious silicone contamination is. Here, the contamination on a gold sputtered microscope spreads beyond the originally contaminated area at a concentration of 32 mg/cm2.

What is a Silicone-Free Industrial Oven?

One of the best ways to prevent silicone contamination in cleanroom environments is silicone-free industrial ovens, like Despatch’s LCC and LCD Benchtop Clean Process Ovens. These ovens are designed explicitly for cleanroom applications. To prevent silicone contamination, manufacturers replace the silicone door with a Viton seal and non-silicone-based sealants.

One of the best ways to prevent silicone contamination in cleanroom environments is silicone-free industrial ovens, like Despatch’s LCC and LCD Benchtop Clean Process Ovens. These ovens are designed explicitly for cleanroom applications. To prevent silicone contamination, manufacturers replace the silicone door with a Viton seal and non-silicone-based sealants.

Key features in these ovens are a stainless-steel interior and exterior, rugged, programmable process controls, and the highest standards in HEPA filtration. (Re-circulated airflow should be 100% HEPA filtered for operation at ISO Class 5 (Class 100) or better within the chamber. Available in air and inert atmosphere configurations, these stackable clean process lab ovens have various tailored options for your needs.

Silicone-free industrial ovens provide a sterile environment for hygienic and sterile manufacturing applications. They prevent the contamination of products and the risks that come with them. They also eliminate the need for costly additional labor and time-consuming repair and rework, increasing productivity and efficiency. Plus, they’ll eliminate the need to stop manufacturing activities and clean equipment. The average cost of stopping production in an automotive manufacturing facility, for example, is about $22,000 a minute. Preventing silicone contamination keeps production on time and within budget, boosting your bottom line.

Bottom Line

Industrial ovens can be a major source of silicone contamination in cleanroom applications, spurring cross-contamination. Silicone contamination is a critical concern in a wide variety of industries, including semiconductor, electronics, and microelectronics. Once silicone contamination happens, it’s difficult and costly to detect. Maintaining an oven’s cleanliness will prevent silicones from contaminating products or substrates, but that’s costly and time-consuming. and remove.

The best approach is to prevent silicone contamination from occurring. Employing silicone-free industrial ovens in your cleanroom application stops silicone cross-contamination in its tracks. With more and more manufacturers turning to lean time and financial restraints, silicon-free industrial ovens can keep production on time and budget, boosting your company’s bottom line.

If you have any questions about silicone-free industrial ovens or need support in choosing the right equipment, please don’t hesitate to contact our technical team for assistance. We are here to help you maximize your efficiency and achieve the highest quality standards in your industry.

Silicon contamination remains a real issue in semiconductor microelectronics manufacturing because it can cause serious problems in the performance and reliability of devices. Silicone can be introduced into the manufacturing process through various sources, including processing equipment, air, and even human skin. Once inside a device, it can cause defects such as increased leakage currents, decreased breakdown voltages, and reduced reliability.

Photo by Toon Lambrechts on Unsplash