Imagine clothing that can adjust to your body temperature, or textiles that can transform into different shapes. This is the promise of shape-shifting fibers.

Meet FibeRobo

Researchers at MIT and Northeastern University have developed a new fiber that shrinks when exposed to heat and regains its shape when the heat is removed. The fiber is compatible with existing textile manufacturing machinery and does not require sensors or other hardware, making it a low-cost and versatile material with countless potential applications.

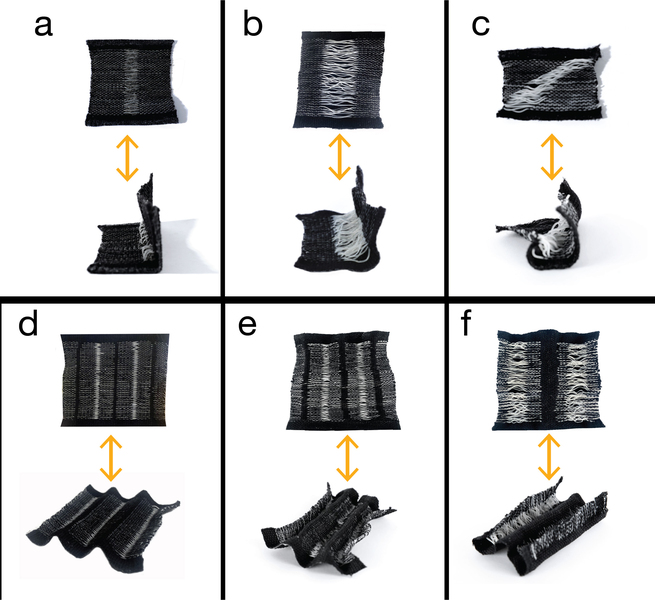

The fiber, called FibeRobo, is made from a composite material of liquid crystal elastomer (LCE). The liquid crystal gives the fiber its shape-changing properties. When heated, the liquid crystal molecules in FibeRobo realign, causing the elastomer to contract and the fiber to shrink. Upon cooling, the molecules revert to their original configuration, restoring the fiber to its original shape.

To create FibeRobo, researchers extrude heated LCE resin through a nozzle while simultaneously subjecting it to UV light curing. The resulting fiber is then coated with oil for a slippery surface and subjected to further UV curing. It is subsequently collected onto a spool and treated with a powder for easy integration into textile manufacturing machinery.

The Future of Fabrication

FibeRobo costs only 20 cents per meter, making it suitable for widespread adoption. It can be incorporated into industrial sewing and knitting machines, as well as non-industrial hand looms and crochet hooks. FibeRobo can also be used to create embroidered products, expanding textile innovation possibilities.

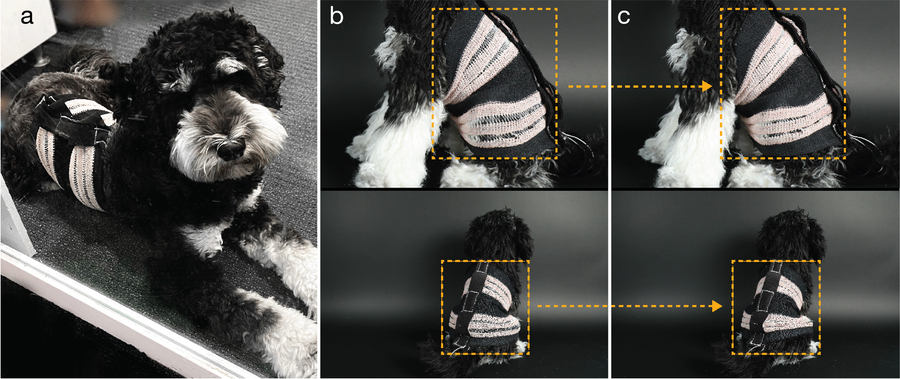

Researchers have already developed a FibeRobo-based dog’s compression jacket that can be adjusted through Bluetooth controls to provide a comforting embrace for pets.

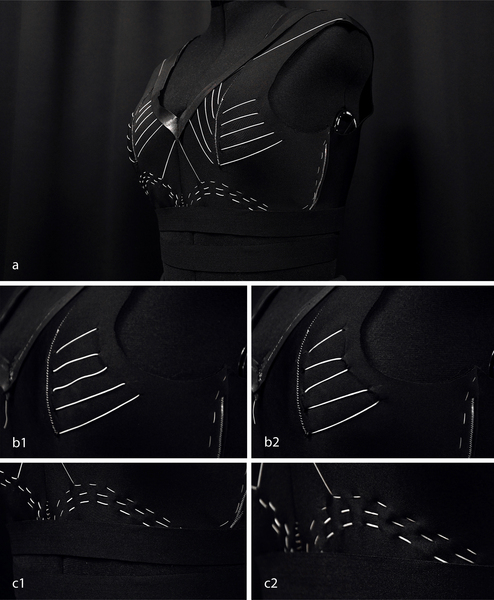

An adaptive sports bra that tightens in response to the wearer’s physical activity has also been created.

With its low cost, versatility, and potential for sustainability, FibeRobo is poised to make a significant impact on the fashion industry. Researchers are exploring ways to make FibeRobo’s chemical components recyclable or biodegradable, and to streamline the polymer synthesis process so that anyone can produce FibeRobo independently. They envision a future where self-adjusting clothing made from FibeRobo perfectly conforms to the wearer’s body.

Article and Image Source: MIT