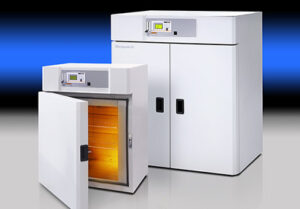

Lab ovens serve as crucial assets in various manufacturing processes. With their ability to enhance product quality and tackle demanding production challenges, they play a vital role in value creation. These ovens are renowned for their high performance, superior uniformity, consistent results, stability, repeatability, and precise temperature control. Choosing a lab oven that can provide these features becomes a strategic advantage for businesses aiming to stay competitive.

The advantages of lab ovens are widely recognized and proven. They contribute to profitability, quality assurance, and competitive edge. Furthermore, lab ovens increase productivity, efficiency, and reliability, while simultaneously promoting energy efficiency and cost reduction. With their versatility and compact design, these ovens find extensive applications in material testing, electronics production, materials processing, medical manufacturing, forensics detection, and research and development.

However, it is important to note that lab ovens typically become outdated due to design considerations and the potential costs associated with repairs. Repairing a malfunctioning lab oven can be time-consuming and expensive. Thus, if your current lab oven has reached a certain age, it might be prudent to begin searching for a new one. Nevertheless, with the vast array of brands and models available in the market, selecting the most suitable and cost-effective oven can be a challenging task.

Common Types of Laboratory Ovens

- Gravity convection ovens: These ovens use natural convection for heat distribution. Hot air rises and circulates within the oven. They are affordable options for applications needing less temperature uniformity. They’re well-suited for processes where you must eliminate cold air from the oven as the air warms inside the chamber. Suitable for applications that require gentle heating and drying, such as sample drying, baking, and curing.

- Forced air convection ovens: Forced air ovens use a fan to blow heated air directly onto the samples, providing rapid and efficient heating. It’s a more efficient and uniform oven than the gravity-convection oven due to the constant air movement. They’re ideal for processes demanding even heat distribution throughout the chamber. Forced Air Ovens are convenient and safe for applications requiring quick heating or drying such as annealing, curing, powder drying, sample conditioning, and out-gassing solidsand liquids.

- Lab vacuum ovens: Vacuum ovens operate under reduced pressure, allowing for lower temperature drying and heat-sensitive applications. They’re ideal for evaporating liquids rapidly, making them suitable for removing trapped solvents, water, gas, and other volatile contaminants from temperature-sensitive products or hard-to-dry substances. They find common applications in drying and purging materials that may react with oxygen or necessitate controlled atmospheric conditions, such as drying delicate electronic components or removing solvents.

- Cleanroom Ovens: Cleanroom ovens are designed to meet stringent cleanliness and contamination control requirements. They feature advanced filtration systems to maintain a clean environment and are commonly used in industries such as pharmaceuticals, electronics, and semiconductor manufacturing.

- Inert Atmosphere Ovens: Inert atmosphere ovens provide a controlled environment with low oxygen and moisture levels. They are used for applications that require the prevention of oxidation or moisture-related reactions, such as annealing, sintering, and heat treating.

- Lab furnaces: are well-suited for situations where consistency and low contamination are necessary for heating materials heating. They are specifically designed for high-temperature applications, exceeding the capabilities of laboratory ovens. They’re ideal for heat treating, reacting studies, sintering processes, and ceramic firing. Pressure range is a crucial consideration with these units.

The most common mounting models for lab ovens include Benchtop Ovens, Floor-Standing Ovens, Wall-Mounted Ovens, Pass-through Ovens and Stackable ovens.

Each Despatch lab oven model brings different things to the table. The choice of oven type depends on the specific requirements of your application, temperature range, sample size, and other factors.

Known for Stability and Repeatability

Despatch laboratory ovens are known for their exceptional stability and repeatability.

Despatch Top Lab Oven Choices:

Recommended for standard laboratory and production applications such as drying, curing, annealing, and materials testing.

- Features forced convection and “uniflow” air circulation for excellent temperature uniformity.

- Standard features include temperatures up to 400°F (204°C), nickel-plated shelves, digital control with LED display, stainless steel interior, high-limit control, and UL and C-UL listing.

- Options include Protocol 3™ control with data logging capabilities, pass-through doors, process timer, CE compliance, and access ports.

LBB model is available in different sizes, ranging from small benchtop models to larger cabinet-sized options.

Provides exceptional temperature uniformity and quick processing time through a combination of forced convection and horizontal airflow.

- Suitable for demanding production and laboratory applications like curing, drying, sterilizing, and aging.

- Standard features include temperatures up to 500°F (260°C), horizontal recirculating airflow, digital control with LED display, high-limit control, nickel-plated shelves, end-of-cycle and high-limit indicators, stainless steel interior, and Modbus communication connection.

- Options include Protocol 3™ control with data logging capabilities, door interlock, access ports, audible and visual alarm, CE compliance, and other features based on specific requirements.

The LAC ovens (without Class A option) should not be used with flammable solvents, combustible materials, or enclosed containers.

Designed for applications requiring minimal contamination in production environments.

- Offers the highest standards in HEPA filtration, providing ISO Class 5 (Class 100) or better operation within the oven chamber.

- Typical applications include die-bond curing, semiconductor packaging processes, depyrogenation, sterilization, and drying for life sciences.

- Standard features include temperature ranges up to 500°F (260°C) for LCC and up to 662°F (350°C) for LCD, lockable disconnect switch, stainless steel interior and exterior, Protocol 3TM control with data logging capabilities, air or nitrogen atmosphere configurations, Modbus communication connection, and UL and C-UL listing.

- Options include three-color process stack light, data acquisition software, silicone-free construction, replaceable HEPA filter, oxygen concentration monitoring system, CE compliance, and more.

- Available in two sizes (1.6 or 5.1 cu ft), with or without HEPA filtration, fast rate HEPA filter, and air or nitrogen atmospheres.

The stackable LCC/LCD Ovens are not to be used with flammable solvents, combustible materials or enclosed containers.

Hazardous Areas & Flammable Solvents (Class A)

Ideal for die-bond curing, semiconductor packaging processes, sterilization, depyrogenation, and drying for life science applications.

- Provides the highest level of HEPA filtration to maintain ISO Class 5 (Class 100) throughout the process cycle.

- Standard features include temperature ranges up to 500°F (260°C) for LCC and up to 662°F (350°C) for LCD, lockable disconnect switch, stainless steel interior and exterior, Protocol 3TM control with data logging capabilities, air or nitrogen atmosphere configurations, Modbus communication connection, end-of-cycle and high-limit audible and visual alarms, and programmable door lock.

- Options include pass-through door configuration, data acquisition software, silicone-free construction, replaceable HEPA filter, and CE compliance.

- Available in air atmosphere or nitrogen atmosphere configurations, both with HEPA filtration. The air atmosphere configuration includes a forced exhaust fan for rapid cooling, while the nitrogen atmosphere configuration lowers oxygen levels to prevent oxidation and offers programmable control of nitrogen and water.

- Features include stainless steel interior and exterior with welded interior seams for contamination protection, Magnehelic™ gauge for monitoring HEPA filter pressure drop, UL and C-UL listed open control panel, and Modbus communications connection for remote monitoring and recording.

Specifically designed to meet NFPA 86 requirements for applications involving flammable solvents or significant moisture removal.

- Available in two sizes: 3.8 cu ft (105 liters) and 12 cu ft (340 liters) with temperatures up to 500°F (260°C).

- Standard features include Class A package meeting NFPA 86 requirements, high limit over-temperature protection, digital control with LED display, PC interface for remote monitoring and recording, and a robust type 304 stainless steel interior.

- Options include Protocol 3TM control with data logging capabilities and USB port, door interlock, 2-inch access ports, 208V full performance package, and CE compliance.

- The oven’s high-volume fan ensures constant horizontal airflow throughout the chamber, making it reliable for demanding production and laboratory applications such as curing, drying, sterilizing, aging, and other process-critical procedures.

Material Testing & Reliability Testing

Stackable chambers offer flexibility for small lot qualification testing, burn-in, reliability testing, and research and development.

- Standard features include temperatures up to 500°F (260°C), digital control with LED display, high-limit control, over-temperature protection, and stainless steel interior with high volume horizontal recirculating airflow for efficient heat dissipation.

- Options include Protocol 3TM control with data logging capabilities and USB port, nitrogen atmosphere for oxidation prevention at high temperatures, PC interface for remote monitoring and recording, redundant hi-limit, and CE compliance.

- The oven’s stackable configuration and automatic modulation damper optimize throughput and equipment use, while the removable rear-wall facilitates fixturing and easy servicing.

Meeting your testing requirements. These lab ovens can be used for applications such as thermal evaluation of electrical insulating materials, testing and other thermal applications where tight temperature uniformity is required.

- Specifically designed to meet NFPA 86 requirements for applications involving flammable solvents or significant moisture removal.

- Available in two sizes: 3.8 cu ft (105 liters) and 12 cu ft (340 liters) with temperatures up to 500°F (260°C).

- Standard features include Class A package meeting NFPA 86 requirements, high limit over-temperature protection, digital control with LED display, PC interface for remote monitoring and recording, and a robust type 304 stainless steel interior.

- Options include Protocol 3TM control with data logging capabilities and USB port, door interlock, 2-inch access ports, 208V full performance package, and CE compliance.

- High-volume fan ensures constant horizontal airflow, making it reliable for demanding production and laboratory applications such as curing, drying, sterilizing, aging, and other process-critical procedures.

The Qmax ovens are not to be used with flammable solvents, materials, or enclosed containers.

Despatch RAF furnaces utilize horizontal recirculating airflow to ensure exceptional temperature uniformity of ±5.6°C at 538°C, making them ideal for annealing, aging, stress relieving, and other critical applications.

- RFF Class A furnaces are specifically designed to meet NFPA 86 requirements for applications involving flammable solvents, featuring a pressure relief panel, purge timer, and exhaust fan.

- Standard features include temperatures up to 538°C (1000°F), 3 models with capacities of 4.2, 19, and 35 cu. ft. (117, 552, and 991 liters), digital control with LED display, high-limit control, audible and visual hi-limit alarm, and a robust 304 stainless steel interior.

- Options include Protocol 3TM control with data logging capabilities and USB port, unique adjustable louvers, pneumatic lift door, chart recorder, quench tank solution heaters, and CE compliance.

While the above-mentioned lab ovens offer a diverse range of capabilities and features, they are just a glimpse of the extensive selection we provide. At Despatch, we understand that each laboratory has unique requirements and specific needs. That’s why we encourage you to explore our website for a comprehensive overview of all our lab ovens.

Should you have any specific inquiries or need personalized assistance in finding the perfect solution for your application, our team of experienced professionals is always ready to help. Feel free to reach out to us, and we’ll be delighted to assist you in making the best choice for your laboratory needs. Your success is our priority, and we are committed to providing the highest quality equipment and exceptional customer support.

Considerations When Buying Lab Ovens

Lab ovens come in a wide variety of shapes and sizes. Choosing the right one from this hodge-podge of equipment is a challenge. The key is focusing on the features that meet your practical requirements and technical performance expectations. Knowing the information below can help you pinpoint the lab oven model that best suits your needs:

- Type and Application

- Size & Volume

- Temperature Requirements

- Heating Uniformity

- Air Flow

- Energy Consumption/Efficiency

- Cleaning & Maintenance

- Safety & Reliability

- Standard vs. Custom-Engineered

Chamber size is a final consideration. Crucial when evaluating lab ovens, chamber size depends, for the most part, on the product or part involved. It’s a consideration you need to get right when buying a lab oven for your company.

Lab Ovens: Building A Competitive Advantage

Lab ovens can help you build a competitive advantage. Manufacturing workhorses, they’re cost-effective tools to help you build value into your products and parts. Versatile and compact, they are ideal for a broad range of manufacturing functions, from simple value-adding processes to complex heating applications that must be tightly controlled and recorded. Medical, electronics, forensic, materials processing, and research and development companies all use lab ovens to set their products apart.

Lab ovens are indispensable in some workflows. So, choosing the right lab oven for you can be confusing. Despatch can help. They’ll work closely with you to find the right lab oven and equip it with the features you need to fit your application exactly.