Staph infections, the bane of life-threatening complications, now face a formidable foe: a new surgical implant with exceptional infection control. Researchers from Washington State University have developed a new infection-resistant implant that promises safer medical procedures.

Traditional implant materials like stainless steel and titanium are susceptible to bacterial colonization despite preventive measures like antibiotic prophylaxis. Infections, known for their unpredictable nature, can vary from immediately after surgery to much later as a secondary infection.

Revision surgery involves removing the infected implant, thoroughly cleaning the area, and sometimes placing a new implant with prolonged antibiotic treatment.

This approach aims to remove the source of infection and provide a fresh, clean surface for the new implant to integrate with the tissue. While systemic antibiotics can be helpful in conjunction with revision surgery, they may not be sufficient to eliminate the infection.

The novel solution ensures long-lasting protection without compromising biocompatibility. The purpose was to combat implant-associated infections, which can lead to a range of adverse outcomes, including implant failure, prolonged hospitalization, or more severe complications.

In conducting the tests in the lab and animal models, WSU researchers impregnated tantalum and copper to the titanium alloy. The results revealed an impressive 87% reduction in staph bacteria growth compared to conventional implants. The tantalum promotes bone and tissue growth, while the copper kills bacteria.

The research co-author, Susmita Bose, highlighted the unique advantage of multifunctional implants that can effectively combat infection and promote bone tissue integration. Traditional implants often require additional treatments or procedures to manage infection, which can prolong recovery and increase the risk of complications.

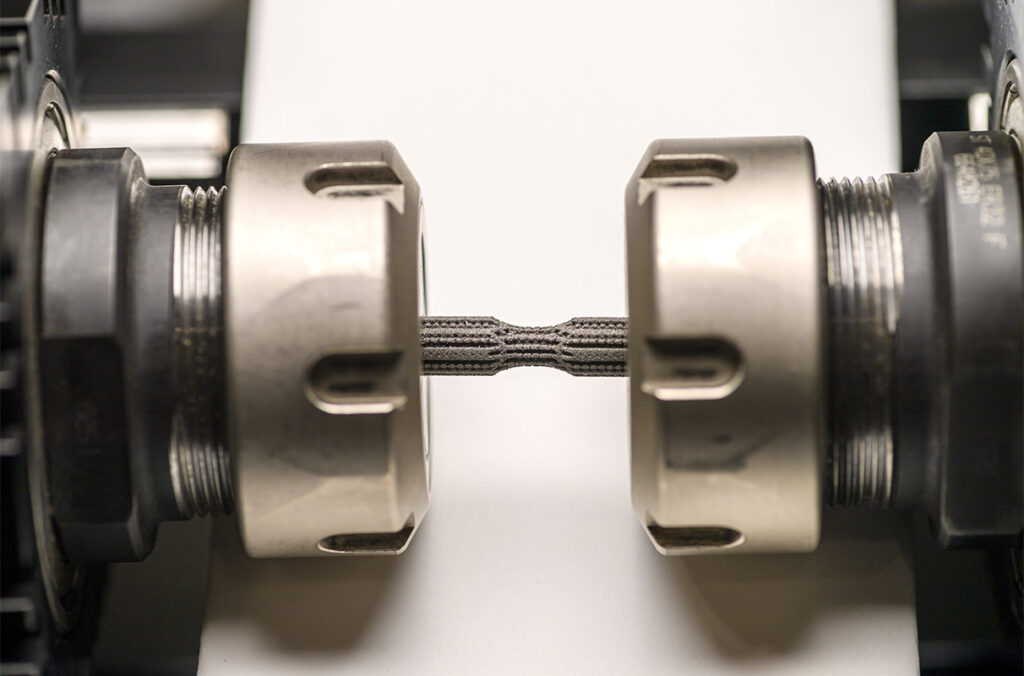

Susmita added that 3D-printed metal implants with antibacterial properties represent a breakthrough in infection prevention. These implants incorporate antimicrobial agents, actively killing bacteria that come into contact with the implant surface.

With 87% bacterial elimination efficacy, these implants hold immense promise for revolutionizing infection control. They have the potential to significantly reduce implant-associated infections, improve patient outcomes, and enhance surgical safety.

The researchers expect to see further refinements in antibacterial implant design and improve the efficiency by 99% while ensuring optimal tissue integration and durability under the rigors of everyday activities.

Image & Content Source: WSU