Biomedical monitoring could soon become a lot less painful experience for the patients, as well as a much simpler procedure for the doctors. Researchers at the Massachusetts Institute of Technology (MIT) have found out how to develop the mass production of cell-sized robots that can be applied in a couple of industries.

The tiny devices, called “syncells” (synthetic cells) by the MIT team, could find its way to pipeline monitoring in the oil industries. They could also be used in medicine and serve as disease detectors in the bloodstream.

The Process of Making Cell-Sized Robots

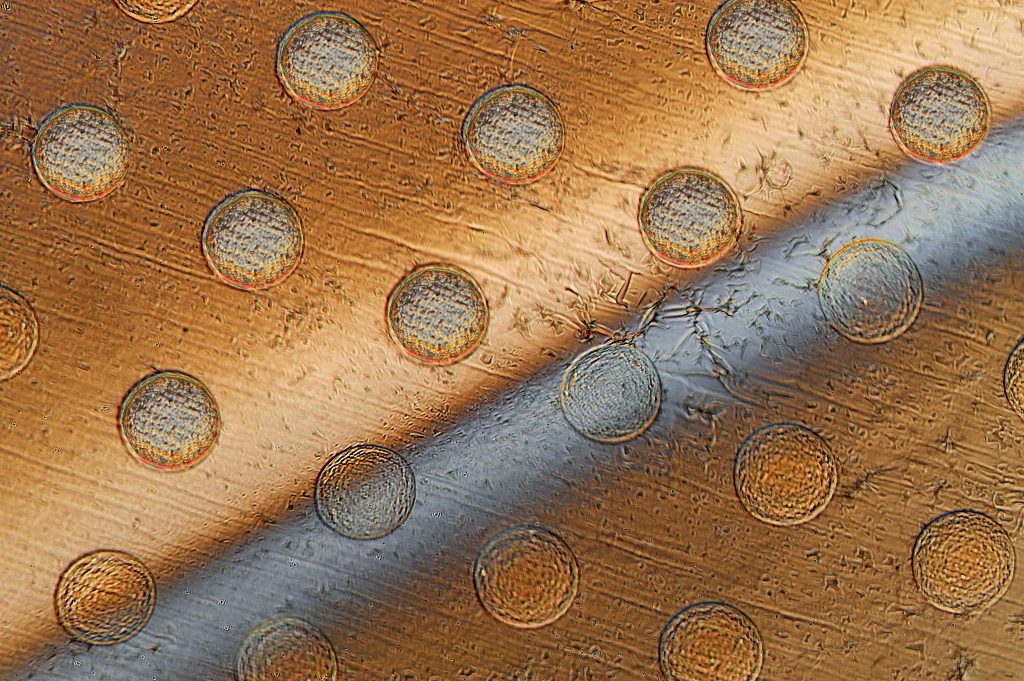

Making such small machines in huge quantities is extremely hard. The MIT team established a method that controls the fracturing mechanism of brittle and thin materials. They found a way to direct the fracture borders so they make tiny pockets of a certain shape and size.

The process, called “autoperforation”, is illustrated in the journal Nature Materials. It’s essentially a system that needs graphene which forms the outer shell of the syncell. The first layer is set down, followed by small polymer specks that contain the electronics and then the second graphene layer is put on top.

Fracturing Graphene at a Nanoscale

Graphene is actually a quite brittle material, and you can control its shape, even at a nanoscale. When a top layer of this material is laid over the polymer specks, which are in the form of pillars, the areas where the graphene can be found (on the edges of the pillars) make long lines of high strain.

The graduate student from the MIT team, Albert Liu best describes it in his own words: “imagine a tablecloth falling slowly down onto the surface of a circular table. One can very easily visualize the developing circular strain toward the table edges, and that’s very much analogous to what happens when a flat sheet of graphene folds around these printed polymer pillars.”

Since the fractures are condensed along the borders, “and the graphene will completely fracture, but the fracture will be guided around the periphery of the pillar”, says the MIT team’s leader, professor Michael Strano.

Lastly, the process creates a round chunk of graphene with clean microscopic cuts. Except for this material, the team found that molybdenum disulfide and hexagonal boronitride can come as a substitute.

The Significance of Cell-Sized Robots for the Medical Industry

The tiny robots are the size of a red blood cell, ranging from 10 micrometers up to 10 times that size. When inserted into a medium, these microscopic objects start to behave like living cells. They even look like ones under a microscope.

In the medical industry, minuscule machines have an array of uses. For example, they can be sent to fight off various types of bacteria by binding to them.

Next, they can float around in the body for a period of a few months to monitor certain bodily functions in patients with the inability to have routine examinations.

What’s more, they can decontaminate hazardous substances in the bloodstream.

The team’s effort can be summarized in professor Strano’s words: “I think it opens up a whole new toolkit for micro- and nanofabrication.”

Image Credit: Felice Frankel via MIT