As compounding pharmacists comply with tighter federal regulations enacted after the 2012 deadly fungal meningitis outbreak, a Florida pharmacist has discovered a clean process oven that is helping his compounding facility meet those higher depyrogenation safety standards.

Pharmacist Vern Allen, chief executive officer for Premier Pharmacy Labs in Weeki Wachee, FL, began investigating his options to meet compliance under the Drug Quality and Security Act, signed by President Obama. He wanted to make the transition from a traditional compounding pharmacy to a 503B compounding facility. To comply with cGMP and USP Chapter 797 standards and the anticipated increased volume of business he had to replace his existing equipment.

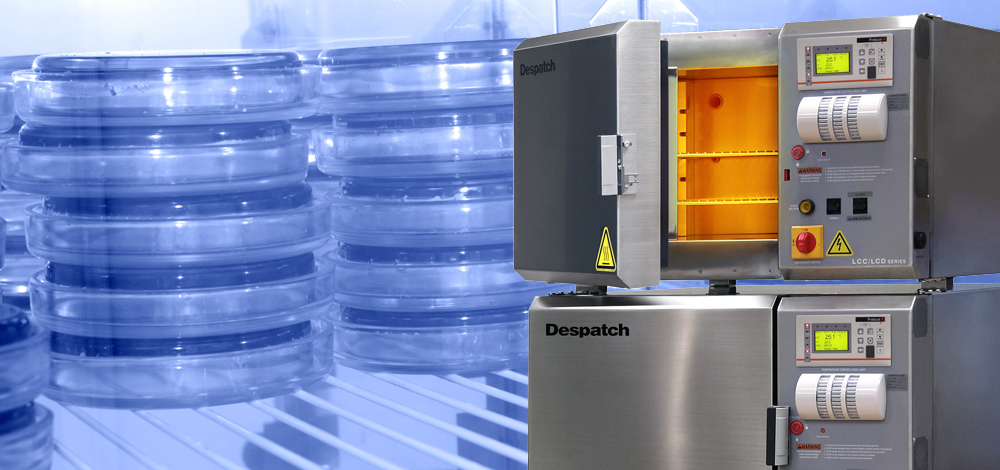

Allen turned to Despatch Industries and purchased a compact, high-performance depyrogenation oven for his clean room. The oven allows his staff to quickly and safely sterilize up to 200 pounds of glass at a time. The stackable bench model saves valuable clean room space and provides room for future growth of his pharmacy business because up to three ovens can be stacked.

Allen wanted a more efficient dry-heat oven with a small footprint to conserve valuable cleanroom space; an oven that could: 1) more quickly depyrogenate glassware (beakers, vials, flasks, prescription bottles, etc) and various metal devices used in the cleanroom in a quantity of 100 or more items per batch, 2) hold 200 lb of glassware per batch, 3) record data about the depyrogenation processes electronically, 4) capture those data on a personal computer, 5) provide specific safety features that would protect the oven operator from injury during any heating cycle, and 6) meet USP Chapter and cGMP standards.

“After reviewing several options, we purchased the Despatch LCC1-51-4 oven which has proven to be perfect for use in our pharmacy at this point in our operation,” said Vern Allen. “I recommend the LCC1-51-4 to colleagues who want ensure the quality and safety of their sterile preparations, keep their pharmacists and technicians safe, qualify the effectiveness of the heating process, easily capture and retrieve electronic data on depyrogenation, and ensure efficiency of operation when a cleanroom oven is required.”

A small workhorse for any clean room, the LCC oven is designed to safely run at maximum temperature all the time. This is why they are a popular choice within the electronics clean process field. Applications often include die-bond curing and other semiconductor packaging processes.

The ovens are designed to meet strict requirements within the life sciences industry, for depyrogenation, sterilization and drying. Although they have been utilized less frequently in pharmaceutical applications, the ovens are finding a new market in the compounding pharmaceutical industry in order to meet 503B regulations related to the manufacturing process.

“It’s quicker than our other dry heat sterilizers,” said Allen, of the LCC oven. “It’s fast, convenient, and it has the necessary safety features. We are able to capture data right off the machine and follow each cycle, making sure it meets protocol. It assures the sterility of each batch load. As we make our way to fully automated manufacturing, this is a piece of equipment that can help us make that transition.”

Allen said any pharmacy performing 503B or 503A sterile human compounding and veterinary compounds would benefit from the LCC ovens. The re-circulated airflow through the integrated HEPA filter ensures the oven chamber is clean before it makes contact with the batch load.

Pharmacist Vern Allen, chief executive officer for Premier Pharmacy Labs uses the Despatch LCC1-51-4 oven to depyrogenate glassware and implements used in sterile compounding. That oven allows the quick and safe depyrogenation of up to 200 pounds of glassware at a time.

Despatch Industries has specialized in thermal processing for over 100 years, providing innovative solutions to critical applications in a broad range of markets and cutting edge technology worldwide.